Product detailed description

We will arrange everything for you, including documentation, simply and without any worries

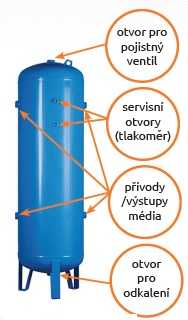

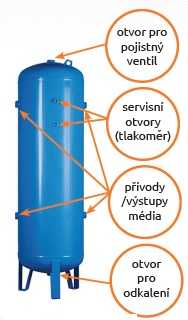

Connections for pressure vessels

- each pressure vessel is equipped with different connections

- the vessel must be fitted with suitable fittings before installation

- according to the relevant standards, each pressure vessel must be equipped with:

- fittings for closure

- safety valve

- a pressure gauge

- the discharge valve

- the manufacturer/supplier is obliged to supply the pressure vessel:

- EC Declaration of Conformity (based on the European P.E.D. Directive)

- the pressure vessel type certificate (EC-type examination) on the basis of which the declaration of conformity was issued

- instructions for use in the relevant language

|

|

|

Pressure assemblies

- after the fittings have been assembled on the pressure vessel, the organisation that carried out the assembly becomes the manufacturer of the pressure assembly

- before commissioning, the pressure assembly must be assessed by an authorised organisation, a notified person (e.g. TÜV, Det Norske Veritas, SZU, etc.)

- the assessment shall check in particular:

- documentation for the pressure vessel

- documentation for all components (taps, connecting valve, pressure gauge)

- whether the components comply with the applicable standards (in particular CSN 69 0010 and CSN 69 0012)

- method and execution of fittings installation according to standards

- assessment of the pressure assembly is a paid service, the price of which is very high for individual cases (usually around 10,000 - 15,000 CZK)

|

|

Airborne Program

- To ease the worries with the legislation of pressure assemblies, we offer the delivery of an air tank fitted with the necessary fittings

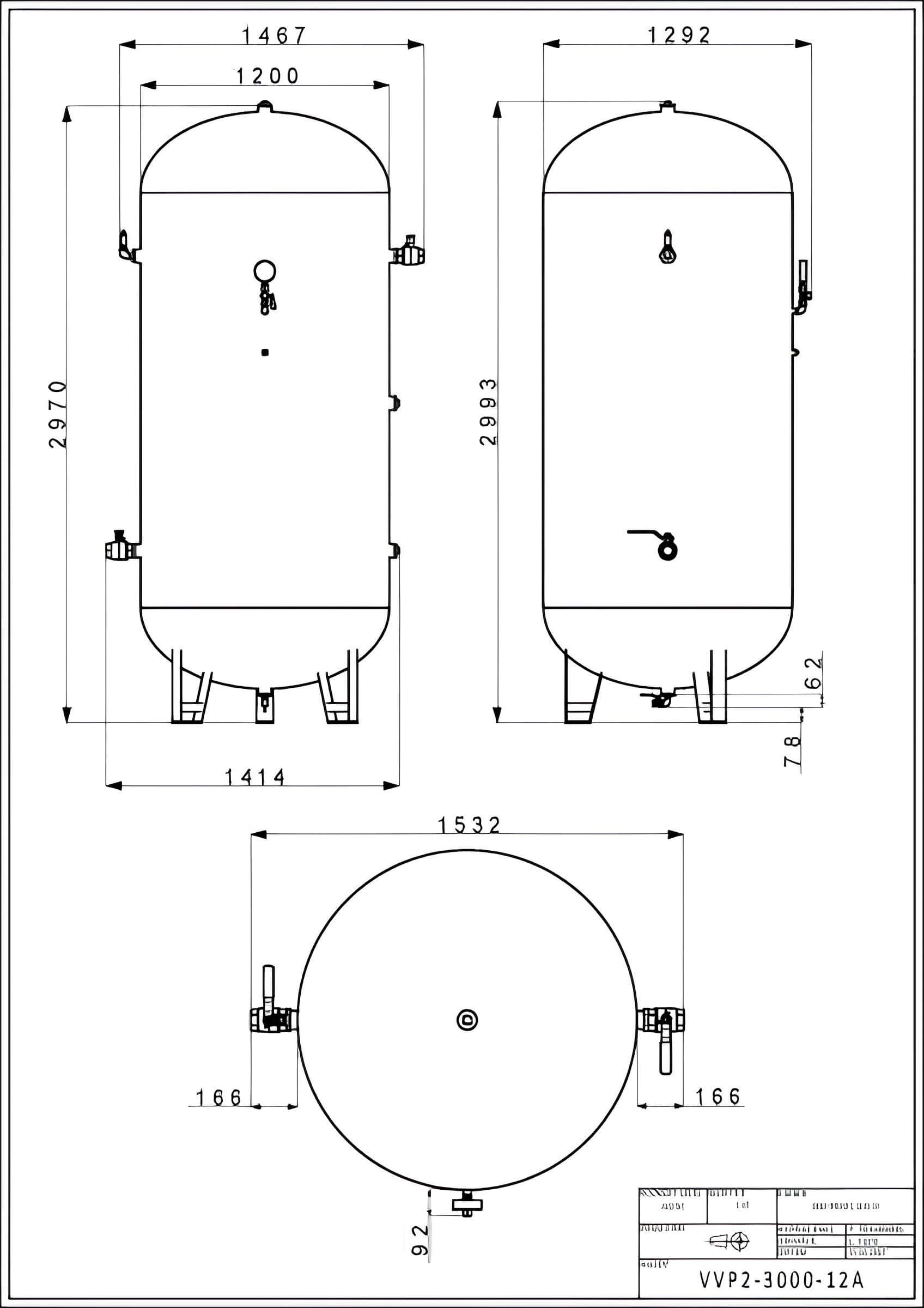

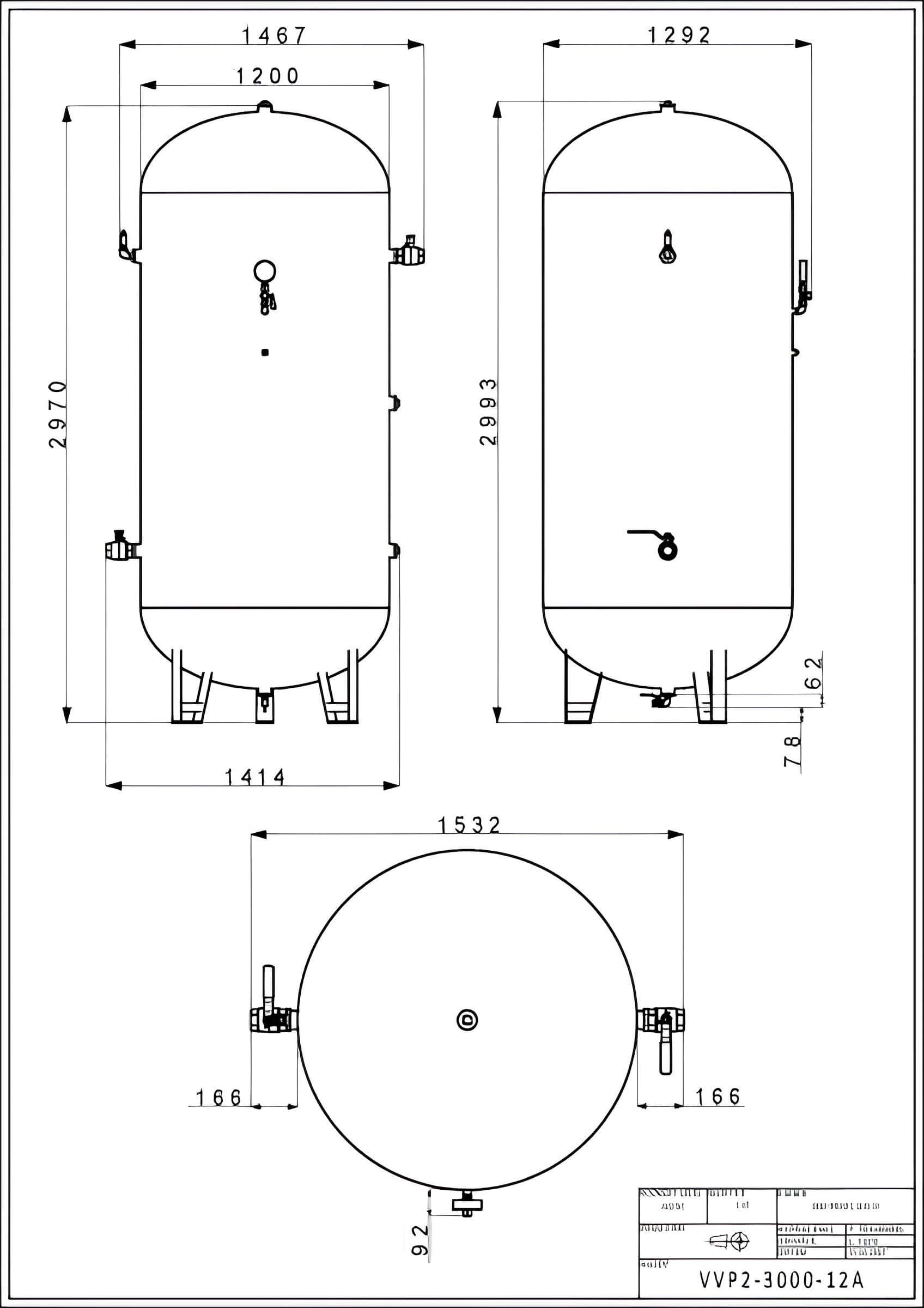

- under the order no. ending with the letter "A" (e.g. VVP270-11A) you will receive the pressure vessel including:

- ball valve at inlet and outlet

- ball valve for sludge removal

- safety valve

- pressure gauge

- test cock

- blanking fittings

- The delivery of the container includes:

- tÜV pressure unit certification

- pressure vessel passport

Due to the mass production, the price for the assessment of the pressure assembly is significantly lower on a flat rate basis between VSK and TÜV - it is only 3.360,- CZK excluding VAT

|

|

Standard program of mounted airmen:

- vVP and VVG series - vertical painted / galvanized

- for a pressure of 11 bar

- volumes 200-270-500-725-900-1000-1500-2000 litres

- detailed breakdown of fittings and their

- the location is in the technical data sheets

- see www.kompresory-vzduchotechnika.cz

Optional program:

- any container from our programme

- location, types and dimensions of fittings according to customer requirements

|

Additional customer obligations related to pressure vessels

- the pressure vessel is a dedicated pressure equipment within the meaning of Decree No. 18/1979 Coll.

- with its operation, the user has the following obligations given by laws, decrees and technical standards:

Revision (according to ČSN 69 0012):

- immediately after installation, carry out the initial and first operational inspection

- 1x yearly operational audit

- every 5 years - internal inspection, leakage test

- every 9 years - pressure test

Organizational / operational matters:

- appoint a review technician

- appoint a person responsible for the operation of pressure vessels

- appoint pressure vessel operators (every 3 years review - carried out by a review engineer)

- keep appropriate records of pressure vessels and ensure the routine operational tasks described in the standard (checks of pressure gauges, thermometers, safety valve, vessel condition, etc.)

|

|

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Almost fifty years of experience

AIR-COM Baglioni is one of the Italian manufacturers of air conditioning systems. The company was formed in 1971 and over the following years began distributing its products worldwide. Thanks to almost fifty years of experience in the field, it guarantees the customer the assurance of quality and precision of the products delivered. Currently, production AIR-COM BAGLIONI is divided into two main segments. On the one hand, the company manufactures accessories for air and cleaning equipment, on the other hand, it produces small compressors suitable for workshops and hobby use, which are outstanding for their quietness. The meticulousness of the products can also be confirmed by the production of airbrushes and other accessories used in fine art.

The productive heart of the company, spread over 2,000 square metres, is a core of 20 employees who oversee the daily production of all products, the quality of which is subject to rigorous and proven certification systems such as ISO 9001, TÜV Germany or CSA Canada. quality is one of the four mottos that AIR-COM BAGLIONI follows. Next to this are flexibility (production depending on customers), costs (constant research to reduce the final price tag) and speed (orders are processed in a shorter time thanks to stored semi-finished products).

The range of products from Air com Baglioni is brought to you by our company Kompresory vzduchotechnika s.r.o.