Spray guns for painters and craftsmen

Spray guns allow precise and uniform application of paints, varnishes or other surface treatments using compressed air. Compared to painting with a brush, they provide faster work and a smoother final surface, which will be appreciated by both hobbyists and professional painters. However, there are several types of spray gun technologies and designs - they differ in the way the paint is sprayed, the compressor requirements and the appropriate application. In this guide , we explain the different technologies (HVLP, LVLP, HTE, APS, RP, etc.), describe the types of storage tanks (gravity, suction, pressure), compare the use for hobby vs. professional paint shops and advise on what to look out for when choosing. Finally, we add practical tips from practice for a perfect paint result. (For detailed information on choosing a spray gun, see also our article How to choose a spray gun for paint application?(Spray guns and how to choose them correctly))

°G0°

Spraying technology: HVLP, LVLP, HTE, APS, RP

There are different spray gun technologies differing in working pressure and air volume. Each acronym stands for a different paint spray system, with different advantages and demands on the compressor (especially pressure and air flow). Below is an overview of the most common types:

|

|

|

|

|

- Conventional (high pressure) guns: Classic older design of spray guns operating with high air pressure. Inlet and outlet pressure is usually around 3-3.5 bar. The advantage is lower air consumption (approx. 150-200 l/min, even a smaller compressor is sufficient) and very fine atomization of the paint (particles ~3-5 µm). The disadvantage is the low spraying efficiency - at most ~45% of the paint ends up on the surface, the rest is dispersed as a mist. Due to high dust (waste) and material wastage, conventional guns today do not meet modern car painting requirements or strict VOC emission standards.

- HVLP (High Volume Low Pressure): High Volume Low Pressure. HVLP guns use high air flow at relatively low pressure, which reduces evaporated paint loss. Typically, they require an inlet pressure of 2-3 bar and a larger air volume (approx. 400-500 l/min) - a more powerful compressor is required and a sufficiently wide hose (min. 8 mm inner diameter) is needed for a stable flow. The gun only operates at ~0.7 bar at the outlet, yet achieves a high spray efficiency of ~65% (meets the requirements of the standards, more paint adheres to the surface and less is dispersed). HVLP spraying is "soft" - it reduces fog formation (dustiness) and saves paint consumption. A weakness may be the slightly coarser atomization - larger droplets (~9-11 µm) can give the impression that the gun is "spitting" material with some cheaper HVLP guns, which is not ideal for fine clearcoats. However, quality HVLP guns can adjust a wide and fine spray beam, making them excellent for base paints and metallics that can be applied evenly and with minimal waste.

- LVLP (Low Volume Low Pressure): Low volume air, low pressure. These guns require less air than HVLP and operate at lower pressure. The inlet pressure is usually around 2 bar, at the nozzle outlet ~1.5 bar. Due to the lower air consumption (~350 l/min) LVLP are also suitable for smaller compressors and for home workshops. The spray efficiency (~55%) is slightly lower than HVLP, but still better than conventional guns. LVLP technology is a kind of hybrid between HVLP and conventional gun - it combines decent spraying efficiency with fine atomization. The droplet size of ~6-9 µm already sufficiently eliminates the "spitting" effect seen with HVLP, so LVLP guns are ideal for acrylic topcoats and clearcoats (often preferred by the paint industry for vehicle painting). Some manufacturers also refer to this technology as RP (Reduced Pressure) or Trans-Tech - under various names, these are guns that operate at lower pressure than conventional systems, but at the same time do not require as huge a volume of air as pure HVLP.

- HTE (High Transfer Efficiency): High Transfer Efficiency. Advanced spraying technology developed to maximize spraying efficiency (often over 70%) and exceed HVLP limits. These guns belong to the low pressure category (similar to LVLP/RP) and meet strict VOC standards due to minimal paint drift. HTE guns (also known as RP) can maintain both fine atomization and high application rates without requiring extreme amounts of air - typical flow rates are around 250-340 l/min (9-12 CFM), which is less than HVLP. They achieve a transfer efficiency of up to 70-80% depending on the type of paint, saving both material and energy (compressed air). The resulting spray is of very high quality - even and without "clouds" (mottling effect) even in metallics with high pigment content. HTE guns provide superior surface quality and outperform both HVLP and older high pressure systems in this regard. This technology is mainly used by professional paint shops that want to achieve perfect paint spread and at the same time reduce losses and air pollution.

- APS (Advanced Pressure System): the latest type of spray guns that can work efficiently over a wide range of pressures. APS technology combines the advantages of both low pressure and high pressure systems - at lower pressures it reduces overspray similar to HVLP, but also allows increased pressure (e.g. 2-5 bar) for rapid application of larger areas or denser materials without compromising spray quality. The optimized APS system ensures even colour distribution and excellent atomization even with pressure changes. These guns typically have all parameters (air pressure, beam width, paint quantity) adjustable over a wide range, making them suitable for both coarse basic spraying and fine finish painting. A practical representative is e.g. the GAV Xtreme APS pistol, an Italian professional pistol operating at 2-5 bar. APS technology is suitable for the most demanding universal applications - allowing one gun to cover a variety of applications from small parts spraying to large-scale painting jobs, with maximum control and efficiency.

Example of a modern APS pistol: Professional spray gun with APS (Advanced Pressure System) technology. These guns can work at low and higher pressures (approx. 2-5 bar) and thanks to their advanced design they achieve uniform spraying of the paint. They allow you to adjust the pressure, beam width and paint volume as required, making them versatile - suitable for fine detail painting and quick spraying of larger areas. The APS system combines the advantages of HVLP (less haze, paint savings) with the power of high-pressure guns, which is especially appreciated by demanding professionals in industry and auto repair.

Paint hopper: gravity, suction, pressure

Spray guns are further subdivided according to the way the paint is dispensed (fed) into the nozzle. Each solution has its own advantages and is suitable for different purposes:

- Gravity feed (upper container): the most common type in modern paint guns. The paint canister is on top of the gun and the paint flows by gravity into the body of the gun. The advantage is a simpler construction and less air pressure requirements (paint does not need to be sucked in). Gravity guns work well with smaller amounts of paint in the container and allow for easier cleaning. Most HVLP/LVLP guns for the auto repair industry are gravity fed - they provide excellent spray control and are comfortable to handle. A limitation may be the volume of the container (usually 125-600 ml) - when painting very large areas, it is necessary to refill the paint more often.

- Suction hopper (lower container): traditional design, where the container is placed under the gun. The paint is sucked into the nozzle from below by the vacuum created by the air flow (Venturi effect). Suction guns used to have a metal container with a larger volume (often 500-1000 ml) and used to be standard. They often have the advantage of a better view of the painted surface (the container does not obstruct the top) and the possibility to preserve the paint in a closed container. However, they need slightly higher air pressure and enough paint in the canister to suck properly - a small volume of paint can cause the gun to "hiccup" as it sucks in air. Today, suction guns are used less, but they still find a place in workshops and hobby painters who are used to them (or for special applications, e.g. spraying from the underside of the surface).

- Pressure tank (remote): here the paint is not directly in the gun, but is transported via a hose from an external tank under pressure. The external reservoir can be a pressure pot or a low-pressure pump that continuously feeds the paint into the gun. The advantage of the pressure system is the ability to spray large volumes of dense materials without constant refilling - ideal for industrial painting of larger areas, lines, spraying multiple parts at once, etc. Pressure fed paint guns are lighter (no canister on top) and allow a stable paint supply even in difficult positions (e.g. spraying ceilings, tank interiors, etc.). The disadvantage is a more complex system - in addition to the gun, you need a paint pressure tank, extra hoses, paint pressure regulation, etc. It is also the most expensive option, which is especially worthwhile if you consume a lot of paint. (If you don't spray paint by the litre, this more expensive option usually won't appeal to you(Spray guns and how to choose the right one)). For normal painting of smaller objects, there is no need for a pressure supply - a gravity or suction gun is sufficient.

Suitable use: hobby vs. professional paint shop vs. industry

How to choose the right type of gun for who will use it and what they will use it for? Another model will be appreciated by the occasional handyman in the garage and another by the professional painter in the auto repair shop. Below are recommendations for different levels of use:

- Hobby use (DIY workshop): for occasional painting of smaller projects (e.g. bike frames, furniture parts, motorcycle accessories) a simpler gun is sufficient. Low air consumption is important, so that a smaller compressor can handle it - LVLP guns (air efficient) or smaller HVLP detail guns are suitable. Focus on versatility: a medium nozzle (~1.4 mm) that handles both the base and the top is ideal. For hobby purposes, a cheaper aluminum alloy gun is often sufficient; however, be aware that it may not have as perfect a spray pattern as the pro models and the service life may be lower. Hobby users should opt for gravity guns - they are easier to maintain and easy to learn how to use. Tip: Don't forget to buy basic accessories such as a hose, quick coupler, filter with pressure regulator and possibly a moisture trap - without clean air and the right pressure, the paintwork will not be of good quality.

- Professional paint shop (car painter): in a professional operation (car service, woodworking shop, etc.) top surface quality, reliability and efficiency are key. It is worth investing in a branded gun with appropriate technology - today HVLP and HTE/RP guns prevail due to meeting emission limits and material savings. Professionals usually use more guns: e.g. with a nozzle of 1.3 mm for base and metallics, 1.4-1.5 mm for clearcoat, 1.7 mm and more for fillers and basecoats. Emphasis is placed on ergonomics (lightweight and perfectly balanced guns minimize fatigue during all-day painting) and spray consistency - the gun must spray the same way every time to ensure that every paint repair goes well. The operation of a paint shop also requires a powerful compressor with a pressure vessel and quality air treatment (filtration, drying) - professional guns need a stable and clean air source. The investment in a more expensive gun pays off in saved paint and time (less defect repairs). In a paint shop, you definitely can't do without an air filtration unit and air separators - see the section on air quality below.

- Industrial painting: includes e.g. painting of machines, structures, serial spraying of products, lines in furniture or metal production, etc. The emphasis is on productivity and durability of the equipment. For continuous use in industry, robust, high-quality guns are chosen, often in combination with a pressurised paint reservoir or directly automatic spraying systems (robot- or machine-controlled guns). The technologies used can be either air (HVLP/RP), airless or high pressure systems for thick coatings - depending on the application requirements. The advantage of air guns in industry is the superior surface quality (e.g. for painting automotive parts), the disadvantage is the lower speed compared to airless pumps when applying very thick layers. In the industry, systems are often combined - airless technology for the basic spraying of large areas, for example, and an air gun for the finishing coat. If you intend to use the gun for long shifts, pay attention to ergonomics and durability of materials - e.g. all-metal guns with a durable finish and easy availability of spare parts. Of course, a powerful compressor with adequate air reserve and perfect air treatment (industrial filters, dryers, oil separators) are essential to avoid the deterioration of expensive paints by dirt or water.

What to look out for when choosing a spray gun

When choosing a particular gun and its accessories, consider several important parameters and features:

- Air consumption and compressor power: Make sure your compressor can supply the required amount of air for your chosen gun. Each model specifies consumption in l/min (at a given pressure) - for example, HVLP guns may require 300-500 l/min, while LVLP can get by with ~200-300 l/min. The compressor should have at least ~30% power reserve so that it does not have to run at full capacity all the time. For long painting runs, a compressor with a larger air reservoir is suitable to compensate for pressure fluctuations. The length and diameter of the hose will also affect the available pressure - remember that every 10 m of hose can cause a loss of up to ~1 bar. Therefore, use the shortest possible hose of the appropriate diameter (ideally 3/8″ or 9-10 mm for higher flow rates). If the gun isn't getting enough air, you'll notice this in the irregular spraying of the paint and fluctuating pressure (the compressor "not keeping up"). In this case, choose either a more economical gun or a more powerful compressor.

- Nozzle diameter: the nozzle size has a major influence on the quality of the material that can be applied with the gun. In general, narrower nozzles (~1.0 mm) are for thin materials and fine work (model painting, lining, stains), medium nozzles (1.3-1.5 mm) universally cover common paints, varnishes and primers, and wider nozzles (1.7 mm and above) are suitable for thicker coatings (fillers, polyurethane paints, adhesives or gilding). If you select a nozzle that is too small for thick paint, the gun will not be able to spray the material (it will clog or "spit"). Conversely, too large a nozzle for thin paint can cause excessive run-off and make it difficult to set a weak beam. Therefore, consider what you will paint most often. The following nozzle diameters are most commonly used for automotive painting:

- 1.2-1.3 mm - for primers, fillers and undercoats

- 1.4-1.5 mm - for topcoats, acrylic paints, clearcoats (finishing coats)

- 1.6-1.8 mm - for fillers with higher dry matter content, 2K base colours, thicker synthetic coatings

Some universal guns allow you to change the entire nozzle and needle set - this allows you to adapt one gun to different applications. But to start with, it is best to choose a nozzle diameter according to 90% of your work (universally 1.4 mm for most paints). If special applications are needed (e.g. metallic vs. clear coat), a second gun with a different nozzle can be purchased over time, or a different nozzle size can be purchased if the model allows it.

|

|

|

- Ergonomics and build quality: when choosing a gun, ideally take it in your hand - it should fit well, not be too front-heavy and the controls (trigger, regulators) should be smooth and fine to adjust. If you will be spraying for a long time in a row, you will appreciate the light weight of the gun (modern models have a body made of light alloys or even composites). The shape of the grip and trigger resistance are also important - a hard trigger will tire your fingers and make it harder to dose. A quality gun also has a precision-machined nozzle and needle (stainless steel or hardened steel) that will last and not wear out quickly. With cheap guns, the spray deteriorates over time (as the nozzle wears out or the channels become clogged). Ergonomics will also affect the resulting quality - with a comfortable gun you will have more confident strokes and a more even spray. For professionals, there are also guns on the market with swivel joints on the air inlet or digital pressure gauges on the gun body, which further facilitate the work. Last but not least, consider the ease of maintenance - is the gun easy to disassemble and clean? Are spare parts (seals, nozzles, needles) available? With reputable brands it is not a problem to get a part later, with no-name guns it can be more difficult.

- Air connection: Most spray guns have a standard threaded inlet for a quick coupler (usually G 1/4″ male thread). So you will need a matching quick coupler (ideally the same type as you use on the hoses and compressor to make everything compatible). We recommend choosing high flow couplings for air tools that do not choke the air flow. Install the coupling using sealing tape (Teflon) on the thread to prevent air leaks. Smaller guns (e.g. airbrush) tend to have different thread sizes, but 1/4″ is standard for regular paint guns. Some people like to use a swivel on the gun to allow the hose to rotate freely and prevent it from twisting - this is also a useful accessory, especially if you're moving the car around and the hose tends to get tangled. Next, look at how the filling of the paint is handled - for the top container it is good to have a standard cap (you can buy a spare) and it is possible to fit disposable inserts or the PPS system from 3M. These details will make the work easier and improve the reliability of the equipment.

- Air quality and conditioning: an often overlooked but essential factor for perfect painting! The compressed air must be clean and dry. Moisture, oil microparticles or rust from the compressor result in paint defects (craters, maps, reduced gloss or poor adhesion). Therefore, the air from the compressor must be treated - at a minimum, a water separator and a particulate filter at the hose outlet. Ideally, use a filter pressure regulator (so-called. FRL unit) placed as close to the gun as possible to set the correct pressure while trapping water, oil and dirt. At the compressor outlet there should be a skimmer with a coarser filter and even automatic drainage. For professional work, also consider an air dryer (refrigeration or adsorption) - this removes moisture to a pressure dew point even below 3 °C, so that water no longer condenses even during long painting. Clean, dry air is the key to the success of any painting job. There are separate articles on this topic in our advice section(How to filter compressed air and Why and how to dry air) - we recommend reading them for detailed instructions on how to achieve ISO 8573-1 (air quality for painting). Remember that even the best gun will spray poorly if it is fed wet and dirty air. Therefore, include the necessary filters, oil separators and possibly a fine carbon filter in your paint kit to achieve absolutely clean air for the topcoat. Check out the category Air treatmentwhere we offer all the necessary equipment - from filters and regulators, to compressed air dryers and complete filtration stations.

Air filtration and control: The use of appropriate filters and regulators is essential to achieve a good paint finish. The picture shows an example of a miniature pressure regulator with a water separator that is mounted directly on the inlet of the gun. This small combination filter captures both condensate and dirt and allows precise pressure adjustment right at the gun. This ensures stable pressure and clean, moisture-free air, which has a positive effect on the final spray quality (no defects caused by water or oil). For professional use, we recommend including main filtration and air drying at the compressor outlet - this prevents water build-up in the hoses and fluctuations in air quality during longer work.

Recommendations and practical tips for perfect painting

Finally, a few practical tips from our own practice, which will be appreciated by both beginners and advanced spray gun users. These tips will help you avoid common mistakes and achieve the best possible result:

- Proper paint preparation and dilution: always follow the paint manufacturer's recommendations for spray viscosity (dilution). Paint that is too thick will clog the gun or create a rough surface, while paint that is too thin may run. Use a spout cup to check the viscosity - with most guns, the paint has the correct density if it flows out of the cup in about 20-30 seconds. Stir the paint well and strain through a fine sieve to prevent any lumps from clogging the nozzle.

- Set up and test spray: before you start painting, do a test spray sideways on cardboard or sheet metal. Set the optimum air pressure (e.g. 2 bar for HVLP - measured on the gun with the trigger depressed), adjust the beam width and paint flow so that the gun sprays a continuous, fine and even spray. A test spray will help you detect too thin or thick paint, poor pressure or beam width before you ruin the final finish. Remember that different colours may require different settings - always fine-tune the gun for your current material.

- Spraying technique: hold the gun approximately 15-20 cm from the surface, guide it at a steady speed and parallel to the substrate. Overlap 15-30% of the previous coat (wet-on-wet overlap) with each new coat to create a uniform layer. Release the trigger outside the object to be painted at the beginning and end of each stroke - this prevents a thicker layer from being applied at the edges. Keep the gun moving at all times, stopping in place will cause a run. It is also advisable to paint in a dust-free environment and ideally at a temperature of ~20 °C for an even gloss. Tip: If you are painting a larger area, divide it into sections and try to work systematically to keep the "wet edge" moving and avoid dull transitions.

- Cleaning and maintenance of the gun: Clean the gun immediately with a suitable thinner after work. Unscrew the container, flush the channels, clean the needle and nozzle (or disassemble them for a thorough cleaning if recommended by the manufacturer). Dried paint residue inside the gun will cause irregular spraying and can completely clog the paint flow. Use cleaning brushes designed for spray guns and take care not to scratch the delicate parts of the nozzle. Occasionally, drip the moving parts (trigger pin, threads of adjustment screws) with a few drops of suitable oil if the manufacturer states so in the maintenance manual. A properly maintained gun will last for years in perfect condition and will still spray the same quality. Never leave paint residue inside to dry - it only takes a few minutes to clean and is an integral part of the paint job.

- Health and Safety: Always wear appropriate personal protective equipment when spraying - especially a good quality respirator (ideally with filters for organic vapours), goggles or face shield and gloves. The fine particles of solvents and pigments are harmful to health and the painting process also produces a flammable aerosol. Ensure good ventilation of the area or use a spray box with extraction. Make sure there are no open sources of fire (sparks, cigarettes) in the vicinity - paint fumes are highly flammable. Work in a clean environment - dust and insects are the mortal enemies of freshly sprayed paint. If you follow these principles, your painting will not only be beautiful, but also safe.

Conclusion: The right choice of spray gun and accessories can significantly affect the outcome of your work. Consider the type of application (from hobby project to industrial production), the compressor parameters, the characteristics of the material to be painted and your experience. If you are unsure, don't hesitate to ask for advice - for example, our article How to choose a spray gun for paint application? (Spray guns and how to choose them correctly) discusses the topic in detail and our customer support (helpline) will be happy to help you choose the optimal equipment. We wish you good luck with your painting and may your new spray gun serve you well!

-

HVLP SGH2000 small spray gun; decorative spraying

HVLP SGH2000 small spray gun; decorative spraying

-

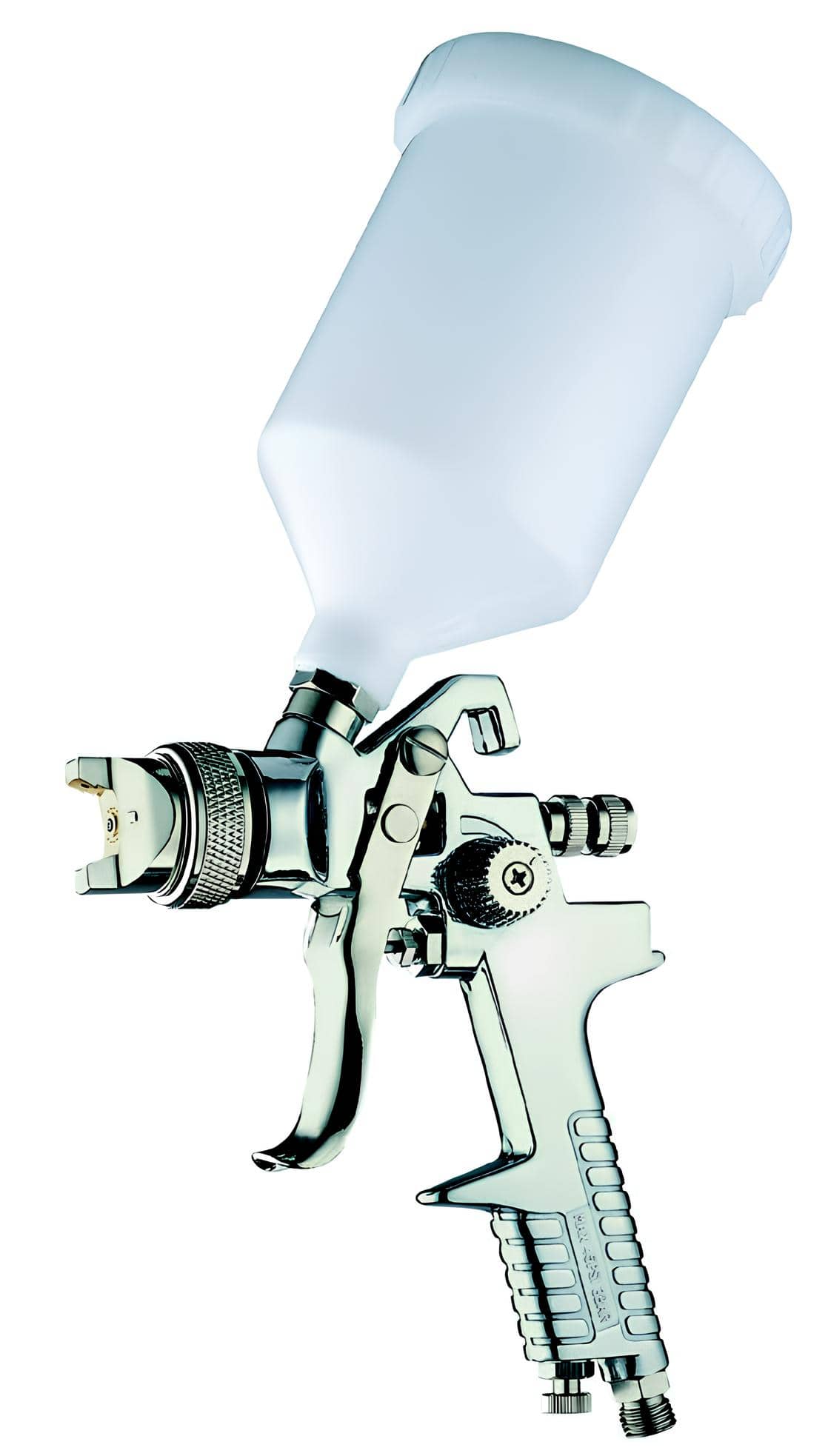

Spray Gun SG990H; with top container

Spray Gun SG990H; with top container

-

SG990S spray gun; with bottom container

SG990S spray gun; with bottom container

-

Spray Gun SGH827; HVLP professional spraying in the paint industry

Spray Gun SGH827; HVLP professional spraying in the paint industry

-

.jpg) Airbrush sets; with accessories in case

Airbrush sets; with accessories in case

-

Minipaint SGMP; HVLP decorative spray gun

Minipaint SGMP; HVLP decorative spray gun

-

Smartpaint SGSP; HVLP decorative spray gun

Smartpaint SGSP; HVLP decorative spray gun

-

Profipaint SGPP; HVLP decorative spray gun

Profipaint SGPP; HVLP decorative spray gun

-

HVLP accessories; for Paint variants

HVLP accessories; for Paint variants

-

Stříkací pistole SGH1002 LVLP; extrémně úsporná stříkací pistole

Stříkací pistole SGH1002 LVLP; extrémně úsporná stříkací pistole

-

Stříkací pistole SGH1000 HVLP

Stříkací pistole SGH1000 HVLP

-

Stříkací pistole SGH501 HVLP

Stříkací pistole SGH501 HVLP

-

Stříkací pistole SG1002; APS pro nejnáročnější univerzální použití

Stříkací pistole SG1002; APS pro nejnáročnější univerzální použití

-

Stříkací pistole SGM502 HVLP

Stříkací pistole SGM502 HVLP

-

Stříkací pistole SGH1000; špičková dekorační stříkací pistole

Stříkací pistole SGH1000; špičková dekorační stříkací pistole

Bestsellers

Nozzle set 0,5 mm for SGH2000 spray gun.

Nozzle set 0,8 mm for SGH2000 spray gun.

Nozzle set with 1.4 mm nozzle for SGH827 low pressure spray guns with HVLP system. For high efficiency of paint transfer and time-saving work. Design with 600 ml nylon upper...

Accessories for SG990H spray gun. Replacement container 600 ml in upper plastic version.

Accessories for SG990-T18 spray gun. Replacement nozzle set includes nut, nozzle and needle in 1.8 mm nozzle version.

Professional spray gun with 1.4 mm nozzle in top-canister version, regulation of air supply, beam shape and paint quantity. Low-pressure HVLP technology to save paint. High...

Small regulator for mounting on spray guns with max. pressure 11 bar, 1/4" thread and 40 mm pressure gauge.

SG990S spray gun with 750 ml bottom container and 1.8 mm nozzle with the possibility of adding additional nozzle sets. Regulation of the colour and shape of the beam. Spray guns...

Spray gun with upper container and 1.5 mm nozzle for painting with the possibility of adding different nozzle sets. Regulation of the colour and shape of the beam. Spray guns...

SG990S spray gun with 750 ml bottom container and 1.5 mm nozzle with the possibility of adding additional nozzle sets. Regulation of the colour and shape of the beam. Spray guns...

Filter for mounting on spray guns and pneumatic tools with a maximum pressure of up to 16 bar and a filtration capacity of 20 µm and 1/4" thread.

Professional spray gun with 1.7 mm nozzle in top-canister version, regulation of air supply, beam shape and paint quantity. Low-pressure HVLP technology to save paint. High...

Spray gun with upper container and 1.8 mm nozzle for painting with the possibility of adding different nozzle sets. Regulation of the colour and shape of the beam. Spray guns...

1.0 mm nozzle set for SGH2000 spray gun.

Practical five-piece set of basic guns with accessories for DIY, craft and general maintenance work. Set includes: 1 pc spray gun with top container, 1 pc air blower, 1 pc blow...

Small spray gun with 0.8 mm nozzle, 100 ml upper container, HVLP technology with a working pressure of 2 to 3.5 bar and a consumption of 227 l/min. Suitable for smaller areas...

Airbrush miniature spray gun for fine spraying and artistic drawings; adjustable container in different directions for good handling. Practical packaging in a small case with...

Nozzle set with 1.7 mm nozzle for SGH827 low pressure spray guns with HVLP system. For high efficiency of paint transfer and time-saving work. Design with 600 ml nylon upper...

Accessories for SG990 spray gun. Replacement nozzle set includes nut, nozzle and needle in 1.2 mm nozzle version.

Accessories for SG990 spray gun. Replacement nozzle set includes nut, nozzle and needle in 1.4 mm nozzle version.

Accessories for SG990 spray gun. Replacement nozzle set includes nut, nozzle and needle in 1.5 mm nozzle version.

Replacement 600 ml container for SGH827 low pressure spray guns with HVLP system. For high efficiency of paint transfer and time-saving work. Design with 600 ml nylon upper...

Basic accessories for the Profipaint HVLP spray gun. Strainer for container

Nozzle set with 2.0 mm nozzle for SGH827 low pressure spray guns with HVLP system. For high efficiency of paint transfer and time-saving work. Design with 600 ml nylon upper...

Spare 750 ml bottom container for SG990S spray guns in aluminium bottom version.

Basic accessories for the Profipaint HVLP spray gun. 1.5 mm nozzle set.

Basic accessories for the Profipaint HVLP spray gun. Jet set 1.3 mm.

Basic accessories for Minipaint HVLP spray gun. Upper container, plastic, 250 ml.

The SGH827-14 spray gun is an extremely economical model with LVLP technology that provides high transfer efficiency and fine atomization of paint at low pressure and low air...

Universal hand spray gun with excellent spray quality for the most demanding applications. Areas of application: car paint shops, industrial painting, e.g. furniture production....

Airbrush in practical set with vinyl hose, containers, tightening wrench, dropper and feeding adapter. Adjustable coating width from 6 to 40 mm. Air inlet 1/4" with special...

The SGH827-14 spray gun is an extremely economical model with LVLP technology that provides high transfer efficiency and fine atomization of paint at low pressure and low air...

Professional spray gun with 1.4 mm nozzle in top-canister version, regulation of air supply, beam shape and paint quantity. Low-pressure HVLP technology to save paint. High...

Professional spray gun with 1.4 mm nozzle in top-canister version, regulation of air supply, beam shape and paint quantity. Low-pressure HVLP technology to save paint. High...

Professional spray gun with 1.4 mm nozzle in top-canister version, regulation of air supply, beam shape and paint quantity. Low-pressure HVLP technology to save paint. High...

Professional spray gun with 1.4 mm nozzle in top-canister version, regulation of air supply, beam shape and paint quantity. Low-pressure HVLP technology to save paint. High...

The SGH827-14 spray gun is an extremely economical model with LVLP technology that provides high transfer efficiency and fine atomization of paint at low pressure and low air...

The SGH827-14 spray gun is an extremely economical model with LVLP technology that provides high transfer efficiency and fine atomization of paint at low pressure and low air...

The SGH827-14 spray gun is an extremely economical model with LVLP technology that provides high transfer efficiency and fine atomization of paint at low pressure and low air...

The SGH827-14 spray gun is an extremely economical model with LVLP technology that provides high transfer efficiency and fine atomization of paint at low pressure and low air...