SCR-22/8PM screw compressor příkon motoru 22 kW, dodávaný tlak 8 bar, objemový výkon 216 Nm3/h

Code: SCR-22/8PM

Related products

Product detailed description

Direct drive 1:1

The SCR-PM series compressors are equipped with highly efficient ALLY WIN screw blocks, which were designed in Germany and have several international patents. The screw block is connected directly to the main electric motor by a tapered coupling, so that there are no losses in the gear train.

IE4 permanent magnet motor

The permanent magnet electric motors used are modern motors with very high efficiency IE4 according to IEC EN 60034, which increases the motor efficiency by up to 3% compared to the motors used in conventional compressors. In addition, the motors are perfectly oil-cooled even at low speeds and thanks to the high IP65 electrical protection, they offer perfect protection against dust and moisture. In addition, the PM motor design does not contain any bearings, which eliminates the maintenance aspect of the motor.

Continuous speed control

Thanks to the infinitely variable speed control by the frequency converter, considerable savings are made, especially by eliminating idling and the possibility to adjust the compressor output pressure.

SCR9000 electronic unit

The modern unit with 7" colour touch screen and communication in Czech language with perfect software allows many user settings, display of machine operation parameters and reporting of possible malfunctions.

Ventilation with speed control

The SCR-PM compressors are equipped with a ventilation system with switching and cooling control according to the needs of the machine. In addition to saving energy, SCR-PM compressors can operate at temperatures up to +45 °C and with very low outlet air temperatures.

Pipes instead of hoses

On SCR-PM compressors you will find only metal tubing instead of traditional rubber hoses. This saves you money on hose replacements in the future and eliminates the risk of hose rupture and subsequent air or oil leaks as much as possible.

Effective oil separation

Thanks to the three-stage oil separation by centrifugal force, gravity and a separation filter, the compressor outlet is highly conditioned compressed air with an oil content of

Additional parameters

| Category: | Compressors for all applications - hobby and industrial |

|---|---|

| Warranty: | 5 years |

| Compressor type: | Screw compressor |

| Pressure: | 8 bar |

| Displacement: | 3,600 l/min |

| Pressure vessel volume: | It isn't |

| Connecting: | 1" |

| Motor power: | 22 kW |

| Mains voltage: | 400/50 V/Hz |

| Lubrication: | Oily |

| Noise: | 66 dB(A) |

| Dimensions: | 1 200 x 800 x 1 100 mm |

| Weight: | 450 kg |

| Engine: | Electric |

| Soundproofed: | Yes |

| Drive: | Direct |

| Air dryer: | No |

| Retrieved from: | Professional |

| Development: | Stationary |

| Frequency converter: | Yes |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Shanghai Screw Compressor Co., Ltd(SCR) is a manufacturing company founded in 2000, focusing on innovation, research, development, production, sales and service in the field of industrial compressors. The SCR production plant is a modern facility with more than 250 employees on an area of over 80,000m2. More than 10% of the staff is in the engineering division with a focus on research and development.

SCR's product portfolio consists of energy-efficient screw compressors, including oil-free and two-stage solutions. SCR manufactures in accordance with ISO 9001 standards, holds CE certification for the European market, UL for the US market, Class Zero certification for oil-free machines and the performance of all machines manufactured is audited by SGS.

After more than 20 years of development, SCR has entered into strategic collaborations with many partners and its products are exported to more than 80 countries worldwide.

In 2018, SCR entered into a strategic cooperation in the form of a joint venture with Japanese manufacturer Anest Iwata, which has implemented its quality and technology control system at SCR, helping to develop and bring new, energy-efficient solutions and even more reliable compressors to the market.

|

|

|

|

|

| 83

countries with trade |

500

distributors |

50 000

users |

80 000

square meters |

140 000

pieces produced |

| 2000

Founding of SCR and start of screw compressor production |

2008

Start of production of oil-free SCR-G compressors |

2015

Screw compressors with PM motors are launched on the market |

2016

Production of the unique SCR-PM2 small compressors |

2018

Joint-venture with Japanese manufacturer ANEST-IWATA |

2020

Development of new 2-stage compressors and turbocompressors with magnetic levitation |

Strategic cooperation with ANEST IWATA

|

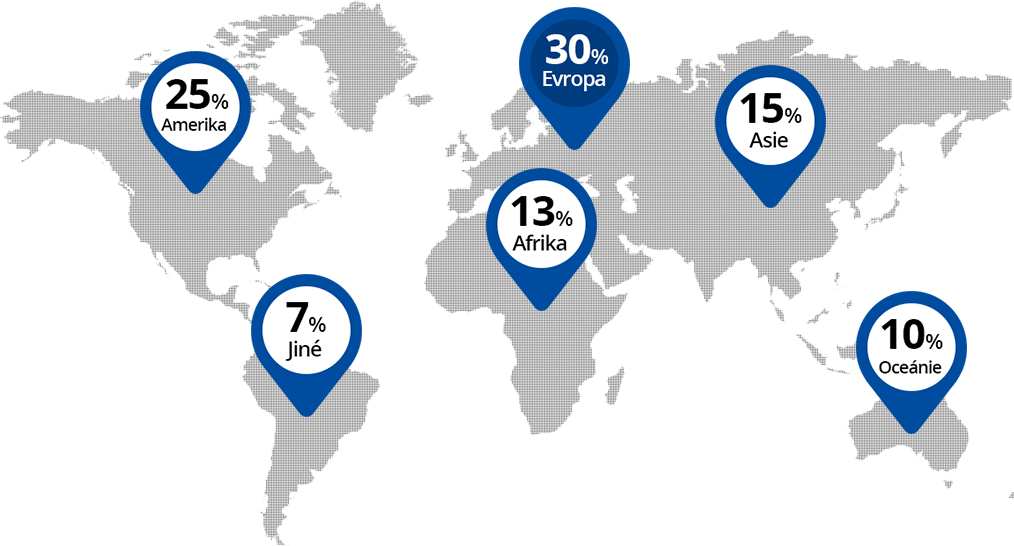

ANEST IWATA's market share in Japan

|

ANEST IWATA Corporation was founded in 1926 and has been in business for over 90 years. Its shares have been traded on the Tokyo Stock Exchange since 1973. The main activities include the production of industrial painting systems, air compressors and vacuum technology. The main production facilities are located in Akita and Fukushima prefectures and together cover over 50,000m2 production areas. In 2018, ANEST IWATA entered into a strategic joint venture with SCR to increase the global market share of both companies in the screw compressor segment and to significantly strengthen the development of energy-efficient compressors and introduce a strict Japanese quality management system into SCR's production plant. |

Global presenceSCR compressors are known worldwide through more than 80 dealerships. In Europe, the SCR brand is officially represented not only in the Czech and Slovak Republics, but also in Great Britain, Spain, Belgium, Finland, Poland, Hungary, Slovenia and Ukraine. |

|

|

Development and innovationSCR is dedicated to innovation in air compressor and screw block technology. Driven by our vision, we look to the future and want to extend our efforts into finding disruptive solutions in the development of new technologies that are addressed to meet the needs of our customers. |

|

SCR brochure - program overviewSCR Compressors | Economical air production solutions Version CZ, PDF - 1,81 MB. |

.jpg)