SCR-EPM screw compressors

.jpg) |

The new range of SCR-EPM compressors has been developed especially with the most efficient compressed air production in industrial plants in mind, using state-of-the-art design features that will provide its user with a significant reduction in the financial costs associated with energy consumption. SCR-EPM machines are coming to the market at a time when savings are needed.

|

SCR screw compressors of the EPM series with variable speed control and power input from 15 to 45 kW |

||||||||||

| Ordering number |

Exit " |

Displacement m³/h |

Displacement l/min |

Pressure bar |

Power input kW |

Dimensions mm |

Weight kg |

Noise db(A) |

||

| d | with | in | ||||||||

| SCR-15/7EPM | 1" | 45 - 180 | 750 - 3000 | 7 | 15 | 1 200 | 800 | 1 100 | 460 | 66 |

| SCR-15/8EPM | 44 - 174 | 733 - 2900 | 8 | |||||||

| SCR-15/10EPM | 35 - 138 | 583 - 2300 | 10 | |||||||

| SCR-18/7EPM | 1" | 78 - 222 | 1300 - 3700 | 7 | 18,5 | 1 200 | 800 | 1 100 | 480 | 66 |

| SCR-18/8EPM | 66 - 210 | 1100 - 3500 | 8 | |||||||

| SCR-18/10EPM | 60 - 174 | 1000 - 2900 | 10 | |||||||

| SCR-22/7EPM | 1" | 90 - 246 | 1500 - 4100 | 7 | 22 | 1 200 | 800 | 1 100 | 560 | 66 |

| SCR-22/8EPM | 84 - 240 | 1400 - 4000 | 8 | |||||||

| SCR-22/10EPM | 66 - 210 | 1100 - 3500 | 10 | |||||||

| SCR-30/7EPM | 1 1/2" | 126 - 372 | 2100 - 6200 | 7 | 30 | 1 300 | 1 000 | 1 370 | 830 | 68 |

| SCR-30/8EPM | 108 - 366 | 1800 - 6100 | 8 | |||||||

| SCR-30/10EPM | 90 - 312 | 1500 - 5200 | 10 | |||||||

| SCR-37/7EPM | 1 1/2" | 99 - 444 | 1650 - 7400 | 7 | 110 | 1 530 | 1 100 | 1 370 | 850 | 70 |

| SCR-37/8EPM | 96 - 441 | 1600 - 7350 | 8 | |||||||

| SCR-37/10EPM | 138 - 390 | 2300 - 6500 | 10 | |||||||

| SCR-45/7EPM | 1 1/2" | 150 - 570 | 2500 - 9500 | 7 | 132 | 1 530 | 1 100 | 1 500 | 890 | 72 |

| SCR-45/8EPM | 144 - 564 | 2400 - 9400 | 8 | |||||||

| SCR-45/10EPM | 180 - 480 | 3000 - 8000 | 10 | |||||||

| SCO-5L | mineral oil, 5 l canister | |||||||||

| SCO-20L | mineral oil, 20 l canister | |||||||||

| * volumetric power is measured according to ISO 1217 | ||||||||||

#ShowMore#

How much is the electricity cost of the compressor ? |

|

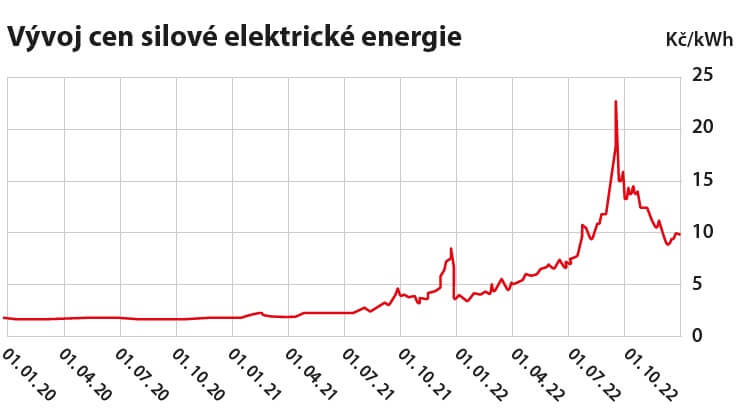

| It is well known that compressors for compressed air production in the crafts and especially in industry are among the machines with the highest power consumption ever. The current energy market situation, with extreme price increases, should make every compressor user think about whether it is worth investing now in improving the efficiency of compressed air production and purchase new and more efficient compressors, thus ensuring not only cost savings but also the competitiveness of their company and eliminating price increases for their products. Before we look together at how SCR compressors can contribute to solving your electricity bill worries, it is first of all necessary to know how much 1 kWh of electricity costs and the annual volume of energy consumption and to deduce what the potential for savings is. |

|

|

|

| By 2021, the aggregate price of electricity including transmission usually ranged in the industry at around 2.50 CZK/kWh. Currently, however, the price of electricity is already at the level of 7 to 10 CZK/kWh and is expected to rise further in the near future. |

|

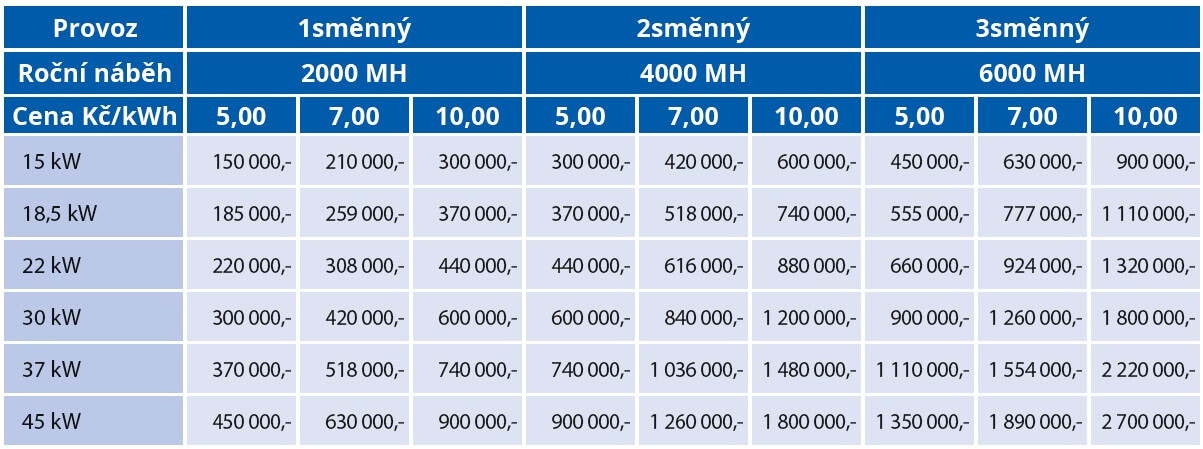

Annual electricity costs

The table below shows the annual costs in CZK for different appliance wattages, types of operation and electricity prices.

SCR-EPM compressors for maximum energy savings |

|

| The new range of SCR-EPM compressors has been developed with the most efficient compressed air production in industrial plants in mind, using state-of-the-art design features that will provide its user with a significant reduction in the financial costs associated with energy consumption. SCR-EPM machines are coming to the market at a time when savings are needed. |  |

|

|

|

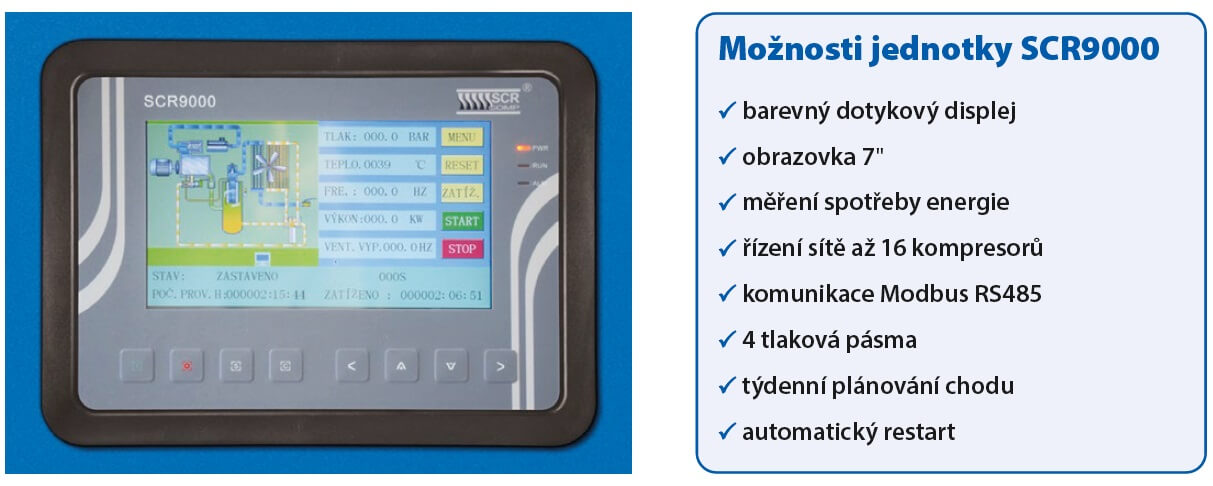

| No idling The wide speed control range of the frequency converter prevents unnecessary energy consumption for no-load operation. |

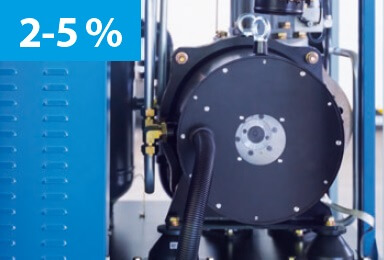

Lossless transfer The direct connection between the screw block and the motor has none of the losses found to varying degrees in other types of gears. |

No unnecessary pressure The SCR9000 control unit allows you to set only the pressure you need. 1 bar of unnecessarily high pressure corresponds to approximately 7% of the energy. |

|

|

|

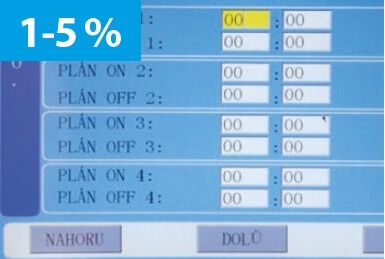

| Elimination of leakage consumption The machine's software allows you to set a precise weekly schedule with scheduled downtime to avoid producing air to cover leaks, e.g. weekend and 4 pressure bands for precise adjustment of the output pressure. |

Efficient IE4 motors The latest generation of permanent magnet electric motors reduces energy costs by several percent compared to IE2 standards. |

Modern cooling The cooling fan is also continuously controlled for even greater savings. If no need, the fan is not running and does not consume any extra energy. |

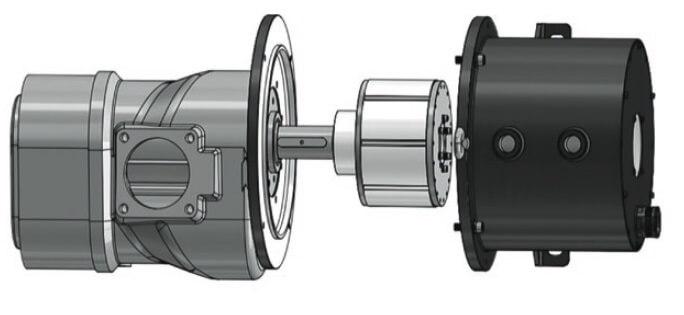

Design layout of the machine

Thanks to the direct connection of the screw block to the electric motor, the SCR-EPM series compressors operate without any energy loss in the gearbox. Compared to compressors with V-belts, clutch or gearbox, this eliminates any maintenance and, in addition to energy savings, the user also saves on machine servicing.

|

||

|

|

|

Screw blocks with extreme performance

Thanks to the direct connection of the screw block to the electric motor, the SCR-EPM series compressors operate without any energy loss in the gearbox. Compared to compressors with V-belts, clutch or gearbox, this eliminates any maintenance and, in addition to energy savings, the user also saves on machine servicing. At the heart of every screw compressor are the screw blocks, which are simply huge on the SCR-EPM range, providing such a huge amount of air produced that they can very often replace compressors with engine power ratings one or two orders of magnitude higher. There are very limited compressors on the market that can compete with the SCR-EPM series in terms of FAD performance.

|

Lossless direct drive of screw compressors

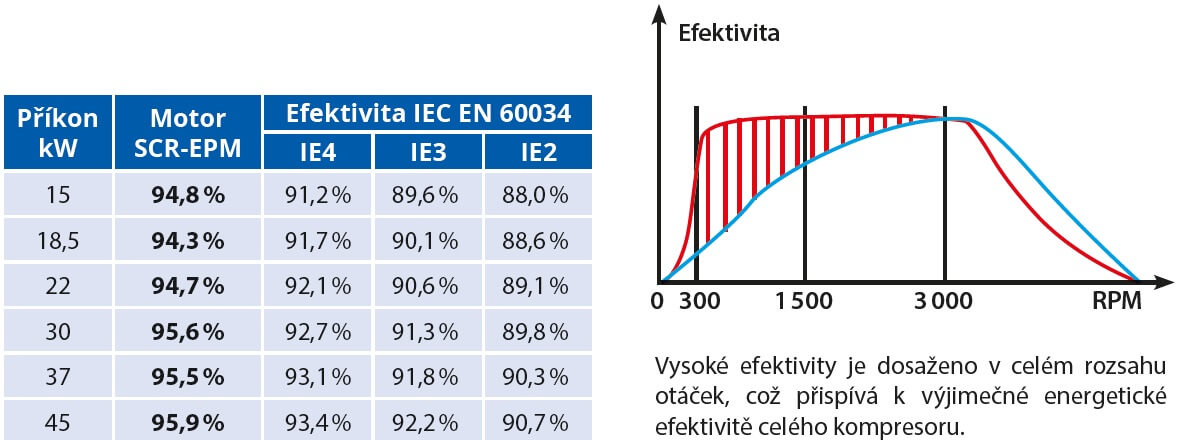

High efficiency is achieved over the entire speed range, contributing to the exceptional energy efficiency of the entire compressor. Thanks to the direct connection of the screw block to the electric motor, the compressors of the SCR-EPM series operate without any energy loss in the gearbox.

Screw compressors EPM - motor with IE4 efficiency

The SCR-EPM compressor range uses the latest technology in oil-lubricated permanent magnet motors, which, due to their design, have an extreme efficiency that exceeds the IE4 efficiency requirements of IEC EN 60034 and outperforms the conventional IE2 efficiency motors used as a standard solution for variable speed compressors by an average of 5-6%.

|

|

Modern electronic control unit

The SCR-EPM series compressors are controlled by the modern SCR9000 electronic control unit with simple operation via a 7" colour touch screen or eight navigation buttons. The SCR9000 unit has many useful features for monitoring compressor status, operating and service settings and necessary alarms.

Efficient technical compressor solutionsEffective oil separation |

|

| Pipes instead of hoses All necessary fluid connections are made by metallic pipes instead of traditional rubber hoses. Thanks to this design change you don't have to worry about any oil leaks, the risk of downtime due to bursting of the hose and, in addition, the internal pressure gradient is reduced by better media flow through a smoother surface. |

|

| Generous machine cooling A generously sized combined radiator is used to cool the oil and the outlet air, perfectly cooled by an efficient fan with infinitely variable speed control. Thanks to the cooling system used, the compressor can be operated at very high temperatures of up to +45 °C. The cooling solution is also responsible for the very low outlet air temperature, which is only up to 10 °C above the compressor inlet air temperature. |

|

Bestsellers

The oil-lubricated screw compressor with extreme volumetric performance and liquid-cooled PM motor IE4 has been developed especially with the most efficient compressed air...

The oil-lubricated screw compressor with extreme volumetric performance and liquid-cooled PM motor IE4 has been developed especially with the most efficient compressed air...