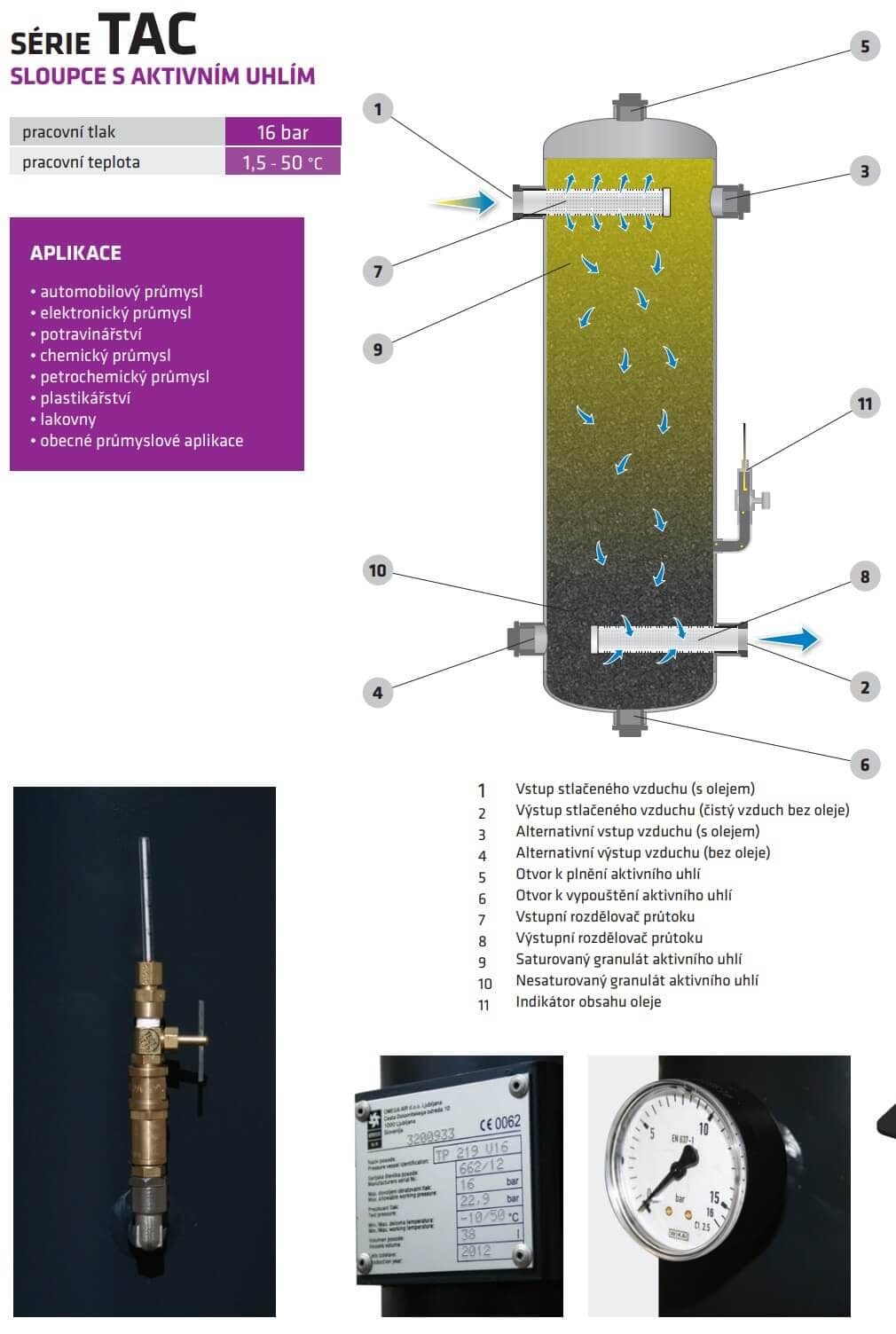

Activated Carbon Towers – Ultimate Oil Vapor and Odor Removal from Compressed Air

Activated carbon towers are a special type of device for final compressed air purification, focused on removing trace contaminants – especially oil vapors and odors. Inside the steel tower is a bed of granular activated carbon, a material with an enormous surface area and excellent adsorption capacity. As compressed air flows through this bed, hydrocarbon molecules (oil vapors) and other organic substances are captured in the pores of the carbon (adsorption process). This is a type of dry separation – unlike mechanical filtration, impurities are physically-chemically bonded to the sorbent surface. The output is extremely clean, oil-free air, suitable even for the most demanding applications. Activated carbon can typically reduce residual oil content to below 0.003 mg/m³ (Class 1 per ISO 8573-1) and eliminate all odors from the compressed air.

#ShowMore#

Advantages

- Significant air quality improvement: removal of oil vapors, odors, and trace contaminants that dryers or mechanical filters cannot eliminate. The resulting air is practically “oil-free” and odorless.

- No electricity or moving parts required – a passive system with silent, continuous operation.

- Simple and robust design with high reliability: the steel pressure vessel withstands stress, and activated carbon is a proven medium with no complex maintenance.

- Enables use of oil-lubricated compressors even in high-purity applications (food, healthcare, etc.) – carbon towers can turn standard compressors into air sources comparable to expensive oil-free models.

Disadvantages

- Does not remove moisture: activated carbon is not a drying agent. If humid air enters the tower, the carbon quickly becomes saturated and loses efficiency for oil removal. A dryer (refrigerated or adsorption) is required upstream.

- Consumable medium – activated carbon has a limited lifespan. Its pores fill up over time, reducing efficiency. The media must be replaced periodically (e.g., every 6–12 months depending on use), adding to operating costs.

- Pressure drop in the system: airflow through the carbon bed causes resistance. With correct sizing, the drop is minimal, but must be considered when sizing compressors.

- Limited range of substances: activated carbon is excellent for organics (oils, hydrocarbons) but does not remove CO, CO₂, or other gases. For special uses (e.g., breathable air), additional filtration (e.g., catalytic) and sterilization are required.

Applications

Activated carbon dryers are used wherever drying alone is not enough and perfectly clean, technically oil-free air is needed. A typical example is the food and beverage industry – compressed air contacts food or packaging and must not affect flavor, smell, or safety. Likewise, in pharmaceuticals and healthcare (e.g., medicine packaging, dental compressors), air must be free from oils and odors. Other uses include surface treatment and painting: e.g., automotive paint shops combine a refrigerated dryer with a carbon tower to ensure dry, clean air for flawless coating. Carbon towers are also used for breathable air (e.g., diving mixtures or breathing masks), but must be combined with drying and filtration stages to remove CO, CO₂, and microorganisms.

Comparison with Other Dryer Types

Activated carbon towers differ from other dryers in their purpose. Refrigerated and adsorption dryers remove moisture, while carbon targets oil vapors and odors. You cannot replace a standard dryer with a carbon tower – instead, they are used together: first drying, then final cleaning via carbon. This combination provides both dry and pure air. Other filters (like mechanical filters) remove particles and liquid oil, but only carbon can capture gaseous oil components. If your application doesn't require top-level air purity, a standard dryer might suffice. Otherwise, activated carbon is essential for achieving the highest ISO classes of compressed air quality.

Reminder: Always install the carbon tower after the main dryer and filters. To perform properly, it requires the cleanest, driest air possible. A fine dust filter should be installed before the tower to capture any carbon particles that may escape into the air stream. Replace the carbon regularly as recommended – this is the only way to maintain consistent performance and protect downstream equipment from oil vapors.

-

RDP condensation dryers; pressure dew point +3 °C

RDP condensation dryers; pressure dew point +3 °C

-

.jpg) Condensation dryers WDF; dew point +3°C with filters

Condensation dryers WDF; dew point +3°C with filters

-

-hankison-susicka-vzduch-kompresor-tllak-kondenzace-rosny-bod.jpg) HDI air dryers; pressure dew point +4°C

HDI air dryers; pressure dew point +4°C

-

RDL condensing dryers; pressure dew point +5°C

RDL condensing dryers; pressure dew point +5°C

-

Cool air dryers; pressure dew point +5°C

Cool air dryers; pressure dew point +5°C

-

MDX air dryers; pressure dew point +3°C

MDX air dryers; pressure dew point +3°C

-

.jpg) ADRY air dryers; smaller adsorption -40°C

ADRY air dryers; smaller adsorption -40°C

-

BDRY air dryers; large adsorption -40°C

BDRY air dryers; large adsorption -40°C

-

MADRY air dryers; membrane -40°C

MADRY air dryers; membrane -40°C

-

Activated carbon columns; activated carbon separation

Activated carbon columns; activated carbon separation

The TAC-1000 dry separator is designed to separate oil vapour from compressed air using activated carbon from the compressor up to a flow rate of 16,667 l/min at a maximum...

Dry separation TAC-110 designed for separation of oil vapours from compressed air by activated carbon from the compressor up to a flow rate of 1 833 l/min at a maximum pressure...

Dry separation TAC-150 designed for separation of oil vapours from compressed air by activated carbon from the compressor up to a flow rate of 2 500 l/min at a maximum pressure...

The TAC-200 dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 3,333 l/min at a maximum...

Dry separation TAC-250 designed for separation of oil vapours from compressed air by activated carbon from the compressor up to a flow rate of 5 333 l/min at a maximum pressure...

Dry separation TAC-300 designed for separation of oil vapours from compressed air by activated carbon from the compressor up to a flow rate of 5 333 l/min at a maximum pressure...

Dry separation TAC-400 designed for separation of oil vapours from compressed air by activated carbon from the compressor up to a flow rate of 6 833 l/min at a maximum pressure...

The TAC-600 dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 9,833 l/min at a maximum...

The TAC-800 dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 12,833 l/min at a maximum...

The TACM-105 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 1,950 l/min at a maximum...

The TACM-12 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 200 l/min at a maximum...

The TACM-150 small dry separator is designed for separation of oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 2,500 l/min at a...

The TACM-200 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 3,333 l/min at a maximum...

The TACM-23 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 400 l/min at a maximum...

The TACM-35 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 600 l/min at a maximum...

The TACM-56 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 1,250 l/min at a maximum...

The TACM-6 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 100 l/min at a maximum...

The TACM-70 small dry separator is designed to separate oil vapours from compressed air using activated carbon from the compressor up to a flow rate of 1,250 l/min at a maximum...

Service kit for the TAC-1000 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for TAC-110 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption processes.

Service kit for the TAC-150 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TAC-200 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TAC-250 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TAC-300 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TAC-400 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TAC-600 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TAC-800 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for activated carbon column TACM-105. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption processes.

Service kit for the TACM-12 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TACM-150 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TACM-200 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TACM-23 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TACM-35 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TACM-56 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...

Service kit for the TACM-6 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption processes.

Service kit for the TACM-70 activated carbon column. Activated carbon is a material in the form of small pellets designed to purify compressed air and gases in adsorption...