Service KIT after a year for adsorption dryer ADRY-105-1R

Code: ADRY-105-1R

Related products

Product detailed description

Service KIT of ADRY-105 adsorption dryer after one year of operation

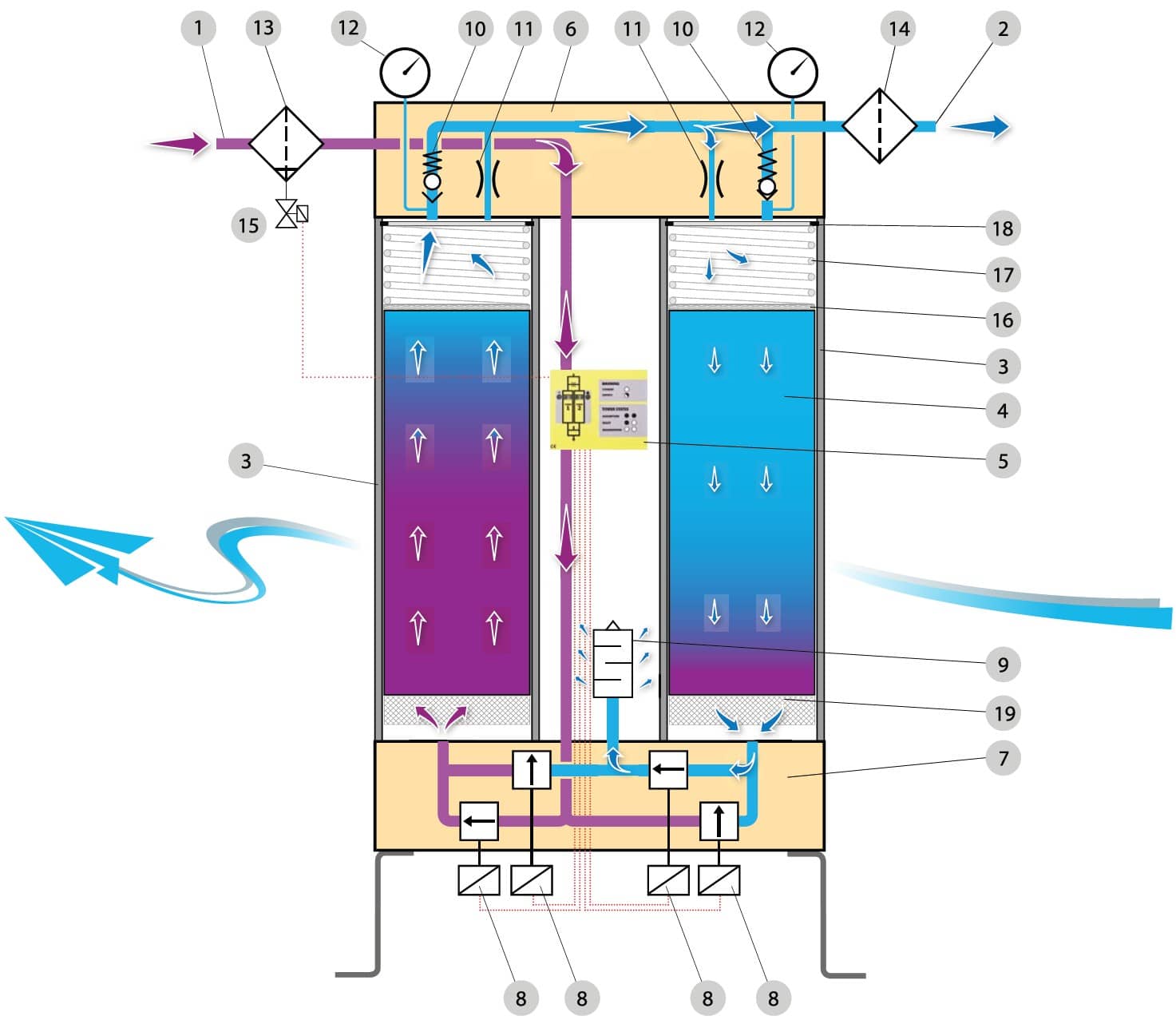

- small adsorption dryers for perfect moisture removal from compressed air with tower regeneration by purging

- standard version with dew point -40 °C; on request with dew point -25 °C or -70 °C

- operating temperature +1.5 °C to +50 °C; electrical voltage 230 V 50/60 Hz, electrical protection IP65

- modular concept allows extremely fast maintenance and reliable operation

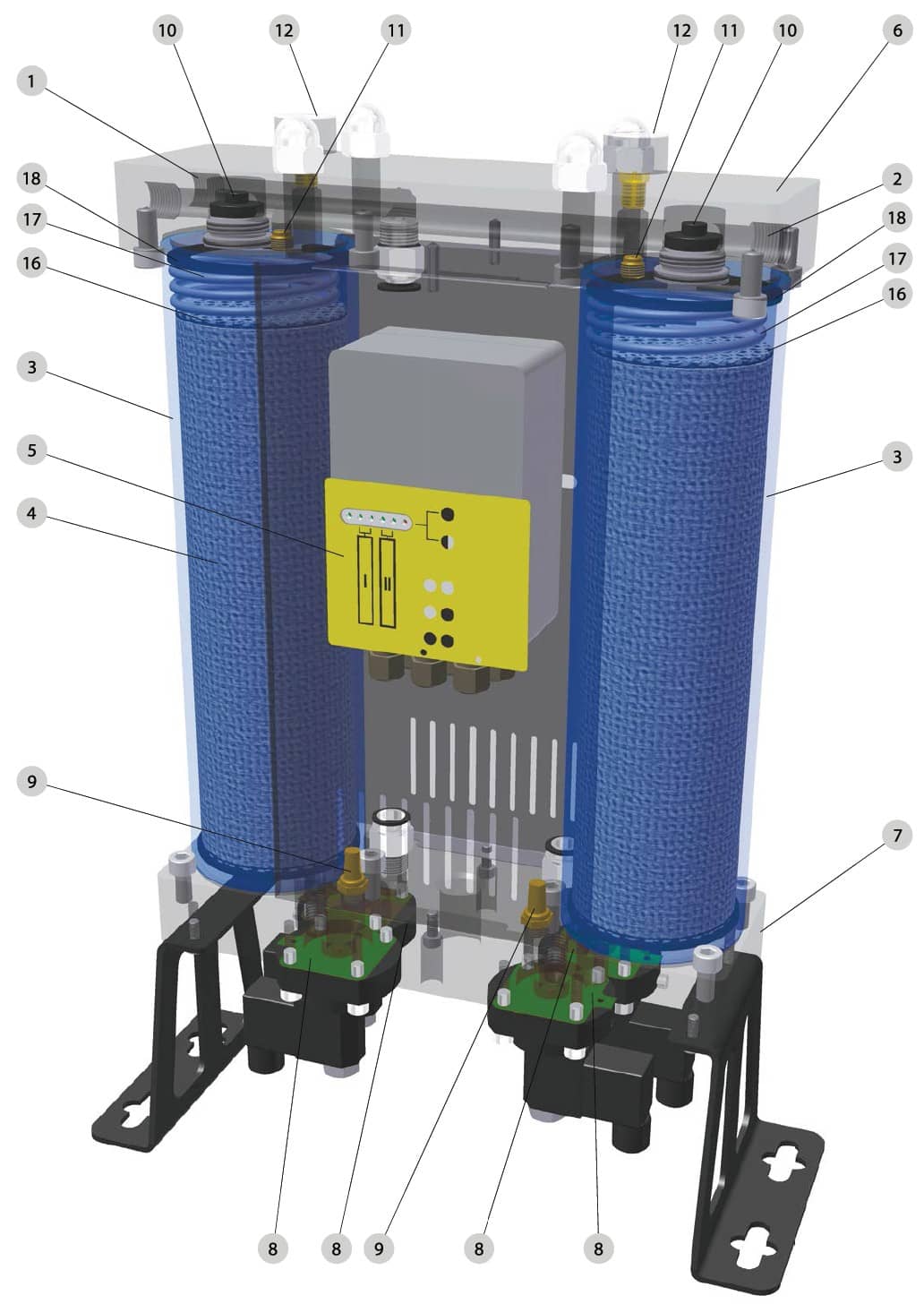

- improved adsorption capacity due to the use of two layers of adsorbent - molecular sieve and silica gel

- aDC 4.0 electronic control unit with dew point sensor connection and webserver access

- 4 control valves with diaphragms made of highly durable NBR reinforced PA, pressure gauges on the top side for column pressure reading

- included in the scope of delivery inlet microfilter AFS 0,01 µm and outlet dust filter AFR 1 µm

- designed for all applications with high minimum humidity requirements in compressed air

- important note: A-DRY dryers consume approximately 15-20% of compressed air for regeneration of the production columns

Correction factor F1 - Working pressure |

|||||||||||||||

| Working pressure bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Correction factor | 0,38 | 0,5 | 0,63 | 0,75 | 0,88 | 1 | 1,13 | 1,25 | 1,38 | 1,50 | 1,63 | 1,75 | 1,88 | 2,00 | 2,13 |

Inlet temperature - correction factor F2 |

Dew point - correction factor F3 |

||||||||||||||

| Working pressure bar | 25 | 30 | 35 | 40 | 45 | 50 | Dew point °C | -25 | -40 | -70 | |||||

| Correction factor | 1 | 1 | 1 | 0,97 | 0,87 | 0,80 | Correction factor | 1,1 | 1,0 | 0,7 | |||||

| Multiply the nominal flow rate by the appropriate correction factor(s) to calculate the correct equipment flow rate under actual operating conditions. Correction flow = nominal flow x F1 x F2 x F3 |

|||||||||||||||

#ShowMore#

Four independently

|

Compact

|

Pressure gauges |

Removable

|

|

|

|

|

| Four high-quality solenoid valves are used to ensure optimal and complete control of the drying process. The individual control of each valve leads to the avoidance of pressure peaks during column switching. | The compact and robust design of the upper and lower control block ensures reliable operation. The cleaning air branch is mounted on the upper block with a check valve so that the nozzle can be replaced if required. | Two pressure gauges located on the top side of the upper control block provide reliable pressure information in each of the production columns. Combined with LED indication, pressure gauges are an excellent tool for diagnosing pressure during dryer operation. | Only two screws need to be loosened to remove the production column from the dryer structure. Replacing adsorption material has never been so easy and quick - you can save valuable time and money. |

Energy savings |

Ten-minute duty cycle |

| A-DRY dryers can be optionally equipped with remote control, where they are controlled by a stand-by signal from the compressor or the master control system. If a stand-by signal is present, air can flow freely through both columns in the inlet to outlet direction. The dryer control unit is in stand-by mode and is ready to switch to normal operation as soon as it receives a signal to do so. The stand-by signal is fed to the A-DRY via a relay contact on the control unit. |

The energy losses of A-DRY dryers are optimised by a 10 minute duty cycle:

The extended duty cycle of 12 switches per hour is also reflected in less wear and tear and therefore more reliable operation. |

Main components

|

|

Easy maintenance

Thanks to the innovative column, the adsorbent change can be carried out in minutes. The entire column can be removed from the dryer by loosening the four top nuts and removing the side locking screws.

The column can be filled with a new adsorbent or completely replaced with a new column.

When the column is removed, there is direct access to the check valve, cleaning nozzle and no need to completely disassemble the entire adsorption dryer.

The valves and diaphragms are located under the bottom of the control block with easy access for quick maintenance or replacement.

|

|

Physical theoryCompressed air contains contaminants such as water, oil and solid impurities that must be removed from the air or reduced to acceptable levels according to the specific requirements of each application. ISO 8573-1 specifies compressed air quality classes for these individual air contamination components. Humidity (water vapour content) is expressed in terms of pressure dew point (PDP), where dew point is the temperature at which the air is 100% saturated with moisture. If the air temperature is below or equal to the dew point, a process called condensation occurs. The reduction of the water content to a dew point of +3 °C is usually achieved with condensing dryers, which are used for most industrial applications. Adsorption dryersTypical applications for adsorption dryers are outdoor installations where there is a risk of water freezing and applications with very high dry air requirements (PDP < +3 °C) such as processes in the food, beverage, chemical, pharmaceutical and electronics industries. The most common type of adsorption dryers are cold regeneration dryers, which are a relatively low-cost investment due to their simplicity and reliability. |

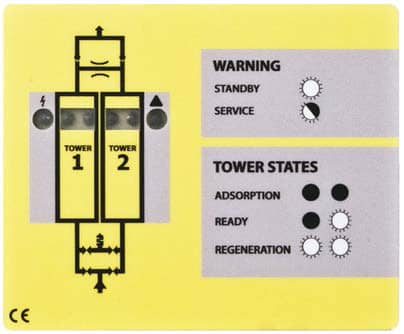

Control unitThe control unit installed on the A-DRY series adsorption dryers, combined with indicators monitoring the operation of the dryer, ensures the operation of the entire plant. The control unit displays status information via six LEDs - one for power, one for alarm/stand-by and four for checking valve status. Each of the four LEDs displays the status of the valve being controlled, allowing the operator to see the current configuration of each valve position at any time. This information, together with the data from the indicators in the individual columns, allows monitoring and analysis of the operation of the adsorption dryer, as well as improving the search for possible faults and malfunctions.

|

Two layers of high

|

Spring system

|

Surface protection |

Precision CNC machining

|

|

|

|

|

| The A-DRY series adsorption dryers use a high quality robust adsorbent to provide stable operation with low energy input. The primary adsorbent layer is made up of a molecular sieve with an extremely high drying potential. To prevent potential degradation of the primary layer by liquid water, the bottom of the column is filled with waterproof silica gel. | During operation, compressive forces are applied to the adsorbent, resulting in movement of the adsorbent material, causing undesirable friction. Adsorbent loss leads to reduced efficiency. For this reason, the A-DRY dryers are equipped with a spring system that applies a constant pressure force to the adsorbent placed in the column, ensuring operation without movement of the adsorbent. |

The production columns and other metal parts are powder coated with epoxy paint. The aluminium components used on A-DRY dryers feature an anodised surface to prevent potential oxidation. |

Contemporary CNC machining guarantees high quality, perfect sealing and reliable operation of all dryer components. Built-in high-quality materials guarantee smooth operation of the equipment. |

Additional parameters

| Category: | Compressed Air Moisture Removal Air Dryers |

|---|---|

| Pressure: | 16 bar |

| Dryer type: | Adsorption dryer |

| In stock: | External warehouse |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Alfa and Omega from SloveniaIn the Slovenian capital, Ljubljana, there is a company specialized in compressed air treatment, production of industrial filters and filter inserts, separators or special membrane dryers and other products. Omega Air was founded in 1988 as a family business and soon secured a place in the industry. Over the years, Omega Air's workforce has also grown with increasing production and today the company employs more than 250 people. |

|

|

Omega products are used everywhereA wide range of applications is typical for Omega Air products. Its products are used in heavy industry as well as by private entities. Slovenia's footprint is thus noticeable in industrial sectors such as electrical, gastronomy, pharmaceuticals, moto and also in the chemical-industrial sector. However, the company's main product is special filters, which are exported all over the world. |

No greenhorn in the industryOmega Air also boasts several proprietary innovations and patents that originate in the development department. The company has also been awarded several times for its innovative solutions at the International Engineering Fair itself, which is traditionally held in Hannover, Germany. The Omega Air product range is brought to you by our air compressors company below. |

What Omega Air produces:

|