Wall mounting kit for AF-10-20 filters

Code: AF-WS

Product detailed description

Why use compressed air filtration ?

Atmospheric air contains impurities such as : dust, various forms of hydrocarbons and water in the form of moisture.

All impurity components are drawn into the compressor and are also contained in the compressed air, even including the oil components that enter the air due to compressor lubrication. All parts interact with each other to form an abrasive and corrosive emulsion that can cause damage to piping, pneumatic systems and the products themselves. Professional compressed air filters designed specifically for screw and piston compressors remove all these impurities. In addition, you can conveniently monitor the clogging status of the filter cartridge using the indication accessories in these pro filters and order a replacement filter cartridge in time for replacement

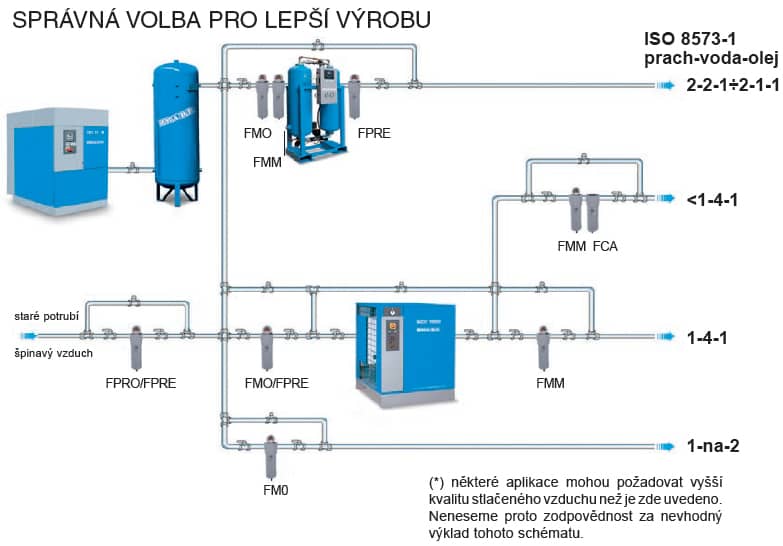

The following air filtration is the answer to more advanced compressor air quality requirements and ensures high efficiency and reliability even for sophisticated compressed air equipment.

|

Coalescence filter AFM - Filtration 0,1 um, oil 0,1 mg/m³ - green identification color Specific use as a pre-filter for condensation dryers, as an oil-removing filter, as a preventive filter to protect pipes, etc. |

|

High efficiency coalescing filter AFS series - filtration 0,01 um, oil 0,01 mg/m³ - red identification color Specific applications as filter after dryer, pre-filter before FCA and ADS, for pneumatic systems, paint shops, pneumatic repair, laser cutting, etc. |

|

AFP pre-filter - filtration 3 um - yellow identification color Ideal duct protection and pre-filter in cases of significant air contamination by liquids or dust |

|

Activated carbon filter AFA - residual oil 0,005 mg/m³ - silver identification color The activated carbon filter is used to remove steam, oil and residual hydrocarbons. Applications in pharmaceutical, food and chemical industries, photographic laboratories, packaging, quality painting, etc.... |

|

AFR dust filter - filtration 1 um - green identification color Use in systems with high dust content, for example the output on ADS adsorption dryers. It is declared as an additional filter after the AFP stage and as a pre-filter for the AFS series. |

||

| The presence of impurities mainly leads to: | 1) - Leaks in the piping 2) - Higher machine maintenance costs 3) - Reduction of product quality and corporate image |

Increasing automation and the application of more sophisticated products are placing ever greater demands on the quality of compressed air.

MARK filters can be the solution to prevent any damage potentially caused by impurities in compressed air.

|

- |

| Dry air - industrial systems - measuring systems - quality painting |

|

| Oil-free air - pharmaceuticals, food industry, chemical industry, packaging technology - galvanic applications - photographic laboratories |

|

| Oil-free air - pneumatic transport - industrial painting - control systems - laser cutting |

|

| Service air - pneumatic tools - jetting - construction industry |

Levels of air purity filtration |

|||||

| ISO 8573-1 | Dust | Water | Oil | ||

| class according to | Dimension | Concentration | Dew point | Water content | Concentration |

| 1 | 0.1 µm | 0.1 mg/m³ | -70°C | 0.003 g/m³ | 0.01 mg/m³ |

| 2 | 1 um | 1 mg/m³ | -40°C | 0.11 g/m³ | 0.1 mg/m³ |

| 3 | 5 um | 5 mg/m³ | -20°C | 0.88 g/m³ | 1.0 mg/m³ |

| 4 | 15 um | 8 mg/m³ | +3°C | 6.0 g/m³ | 5 mg/m³ |

| 5 | 40 | 10 mg/m³ | +7°C | 7.8 g/m³ | 25 mg/m³ |

| 6 | - | - | +10°C | 9.4 g/m³ | - |

Filtration capacity of individual filter series |

|||||||

| Series | Filtration¹ | Efficiency | Residual oil¹ | Pressure loss | Class according to ISO 8573² | ||

| um | % | mg/m³ | mbar | dogs | Dust | Oil | |

| AFM | 0,1 | 99,9 | 0,1 | 80 | 1,16 | 1 | 2 |

| AFS | 0,01 | 99,9999 | 0,01 | 90 | 1,30 | -1 | 1 |

| AFA | - | - | 0,005 | 120 | 1,74 | - | -1 |

| AFP | 3 | 99,9 | - | 40 | 0,58 | 3 | - |

| AFR | 1 | 99,9 | - | 80 | 1,16 | 2 | - |

Technical data for compressed air filters |

||||||||||||

| Type | Air flow | Pressure | Connecting | Size | Weight | |||||||

| - | l/min | m³/h | cfm | bar | dogs | thread | AND | B | C | D | kg | |

| 10 | 1 000 | 60 | 35 | 16 | 232 | 3/8" | 187 | 88 | 20 | 60 | 0,7 | |

| 13 | 1 300 | 78 | 46 | 16 | 232 | 1/2" | 187 | 88 | 20 | 60 | 0,7 | |

| 20 | 2 000 | 120 | 71 | 16 | 232 | 3/4" | 257 | 88 | 20 | 80 | 0,8 | |

| 33 | 3 300 | 198 | 117 | 16 | 232 | 1" | 263 | 125 | 32 | 100 | 1,8 | |

| 60 | 5 580 | 335 | 197 | 16 | 232 | 1" | 363 | 125 | 32 | 120 | 2,5 | |

| 85 | 8 500 | 510 | 300 | 16 | 232 | 1 1/2" | 461 | 125 | 32 | 140 | 2,5 | |

| 130 | 13 000 | 780 | 459 | 16 | 232 | 1 1/2" | 640 | 125 | 32 | 160 | 3,2 | |

| 170 | 16 600 | 996 | 586 | 16 | 232 | 2" | 684 | 163 | 42 | 520 | 5,1 | |

| 250 | 25 000 | 1 500 | 883 | 16 | 232 | 2" | 935 | 163 | 42 | 770 | 7,1 | |

| 400 | 40 000 | 2 400 | 1 413 | 16 | 174 | 3" | 1 000 | 240 | 58 | 780 | 14 | |

1 ) Reference conditions : pressure 7 bar (102 psi), temperature +20°C

2 ) ISO classes related to water content do not apply to filters

Max. operating temperature : +66°C for AFP, AFM, AFS series, +35°C for AFA series

Min. working temperature : +1°C

| Correction factors for flow at pressures other than the reference pressure | ||||||||||||||||

| Working pressure (bar) | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | |

| Working pressure (psi) | 29 | 44 | 58 | 73 | 87 | 102 | 116 | 131 | 145 | 160 | 174 | 189 | 203 | 218 | 232 | |

| Correction factor | 0,38 | 0,52 | 0,63 | 0,75 | 0,88 | 1,00 | 1,13 | 1,26 | 1,38 | 1,52 | 1,65 | 1,76 | 1,87 | 2,0 | 2,14 | |

The new flow value is calculated by multiplying the correction factor to the real pressure value with the flow at the reference filter pressure.

Standard parts of each filter

|

|

Fixed bodyFor connection to pipelines, with high flow rates and low power losses. |

|

A moving part of the bodyafter liner replacement, easily removable, with pressure relief device for greater safety and condensate drainage. |

|

Filter insertwith double stainless steel support, with pressure connection and for easy replacement. |

|

Automatic dischargewith a float for the discharge of separated liquids. |

|

Anti-corrosion surfacelacquered body surface for long life. |

Additional parameters

| Category: | Compressed air filtration pressure 16 to 64 bar |

|---|---|

| Version: | Accessories |

| Certification: | CE-PED-H, ISO 8573-1 (IUTA) |

| Functions: | Fast and elegant wall installation |

| Designed for: | Filters in sizes AF-10 to AF-20 |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Alfa and Omega from SloveniaIn the Slovenian capital, Ljubljana, there is a company specialized in compressed air treatment, production of industrial filters and filter inserts, separators or special membrane dryers and other products. Omega Air was founded in 1988 as a family business and soon secured a place in the industry. Over the years, Omega Air's workforce has also grown with increasing production and today the company employs more than 250 people. |

|

|

Omega products are used everywhereA wide range of applications is typical for Omega Air products. Its products are used in heavy industry as well as by private entities. Slovenia's footprint is thus noticeable in industrial sectors such as electrical, gastronomy, pharmaceuticals, moto and also in the chemical-industrial sector. However, the company's main product is special filters, which are exported all over the world. |

No greenhorn in the industryOmega Air also boasts several proprietary innovations and patents that originate in the development department. The company has also been awarded several times for its innovative solutions at the International Engineering Fair itself, which is traditionally held in Hannover, Germany. The Omega Air product range is brought to you by our air compressors company below. |

What Omega Air produces:

|