Blow guns for compressed air

Blow guns are an essential tool for fast and efficient cleaning of work surfaces, machines and products with a stream of compressed air. Keeping a workshop or plant free of dust, sawdust, dirt and other debris would be difficult without them - there's no easier solution than compressed air blowing. These guns are used in hobby workshops and garages as well as in demanding industrial applications. No compressor should be without a quality blow gun - whether you need to blow dirt off the occasional workbench in your home workshop or clean CNC machines and production lines on a daily basis. In this category, you will find a wide selection of blow guns and accessories (different types of nozzles and pressure regulators) so that you can tailor your blowing to your needs. Below, we will introduce the different types of guns and nozzles, their functions, advantages and suitable applications - for hobby users and B2B customers - and add practical tips and recommendations for expanding your product range.

°G0°

Choosing a blow gun according to design and material

When choosing a blow gun, the material and design of the gun body plays a big role. Three variants are most commonly found on the market:

- Plastic blow guns: The gun body is made of durable plastic (e.g. hardened polyamide). The plastic guns are lightweight and do not get cold or burn the hand even with large temperature fluctuations. This is especially useful where the environment is either very cold or hot - the metal surface could make an unprotected hand uncomfortably cool or burn. However, the plastic version generally does not achieve the same durability as the metal ones - for hobby use or occasional blowing they are sufficient, but in an industrial hall with all-day operation and rough handling (frequent falls on the ground, etc.) the plastic will wear out faster. Summary: Plastic guns are ergonomic in extreme temperatures and lightweight, but less suitable for heavy duty use.

- Blow gun made of die-cast aluminium: The gun body is made of die-cast aluminium. It is a standard robust design that offers good value for money. Cast aluminium is strong enough for normal use in the workshop or factory. The disadvantages may be thermal conductivity - it cools in the cold, but can heat up in the sun or at the machine - and slightly higher weight compared to plastic. Summary: Aluminum guns (die cast) are a versatile choice for most applications from hobby to industrial when you want decent durability at an affordable price.

- Forged aluminium guns: The gun body is forged from aluminum alloy, ensuring maximum strength and durability. Forged pistols represent the highest quality design - they can withstand rough handling, drops and long-term intensive use. They are suitable for the most demanding conditions of industrial plants, service stations and workshops where the gun is used on a daily basis. They are priced higher than cast models and the weight is similar (still significantly less than steel). Summary: Forged blow guns are ideal for professional and industrial applications where the highest demands are placed on reliability and durability.

Note: Steel is hardly used as a pistol body material because of its high weight. However, some small parts of the gun (e.g. trigger lever or replaceable nozzle) may be made of steel or brass to withstand the mechanical stress.

|

|

|

|

|

Design options and functions of blow guns

In addition to the body material, it is good to note the design features of the blowguns. Different models may offer different nozzle lengths, interchangeable attachments or flow control. When choosing, consider in particular:

- Nozzle length (short vs. extended gun): classic blowguns have a short metal nozzle (e.g. lengths of around 20-40 mm), suitable for normal close range blowing. For special purposes, there are extended blow guns with a long tube (100 mm, 300 mm or more) that allow you to blow into deeper places, narrow crevices or, on the contrary, to keep a greater distance from the object to be blown (useful e.g. for very hot surfaces or for blowing ceiling filters, etc.). Some models (e.g. the ABG series) are available in both short and extended versions - so you can choose the length of the tube according to your needs. If you need to blow in hard-to-reach areas, be sure to reach for the extended gun or the interchangeable long nozzle.

- Interchangeable nozzles: many modern guns allow you to change nozzles (typically with M12x1.25 thread). Guns with interchangeable nozzles are very practical - you can achieve different airflow characteristics with one tool by simply changing the nozzle. In our offer you can find sets of exchangeable nozzles in various designs (see next chapter), which fit the standardized thread of the blow guns. Advantage: One gun can serve as a powerful narrow jet blower, a quiet blower with muffled noise, a safety blower with a shield and as an extended range tool - just choose the right nozzle.

- Air flow control: On some models, the intensity of the blow can be adjusted directly on the gun. For example, the BG269E blow gun is equipped with an integrated control element (rotary screw/valve) that can be used to throttle or fully open the air flow from the nozzle. This gives you better control - for gentle blowing of sensitive parts, choose a lower flow rate, for rough cleaning, choose full power. Alternatively, the regulation can also be solved externally by means of miniature hose pressure regulators (see category BLP pressure regulators for guns). The control option is especially appreciated by professionals who need to precisely adjust the bang for the task and also save compressed air when full power is not required.

- Ergonomics and shape: the ergonomics of the gun are also important for comfortable work. Most blow guns have a pistol grip with a lever trigger. Some models may have a rubberised handle for a firmer grip or a swivel hose connector to prevent the hose from twisting when moving. More expensive professional pistols often think about ergonomics in detail - the shape of the grip fits the hand, the trigger can be squeezed smoothly and it has a loop for hanging. If you will be using the gun for a long time and often, pay attention to ergonomics (a lighter plastic one may tire your hand less, but requires more care in handling).

Types of blowing nozzles and their applications

The nozzle of the blowing gun has a major influence on the nature of the air flow, the noise level of the blowing and the safety of the work. Therefore, there are several types of nozzles, each suitable for a different application. Most often you will encounter the following species:

| Nozzle type | Characteristics and uses |

|---|---|

|

Basic nozzle

|

Simple straight nozzle with a small central hole (e.g. Ø 1.5 mm). It creates a concentrated, narrow stream of air with high speed and force. Suitable for targeted blowing of smaller areas, crevices and heavily stuck dirt. The disadvantage is the higher noise level (up to 90 dB at 4 bar) and also the smaller current area. |

|

Soundproof nozzle

|

Nozzle to reduce blowing noise. It contains an internal liner (e.g. made of sintered bronze) that splits and slows down the airflow, thereby dampening the noise to a level of around 70 dB. However, in exchange for quiet blowing, the power and speed of the jet decreases - so it is suitable where hearing protection is a priority and high blowing power is not needed (e.g. dust blowing). |

|

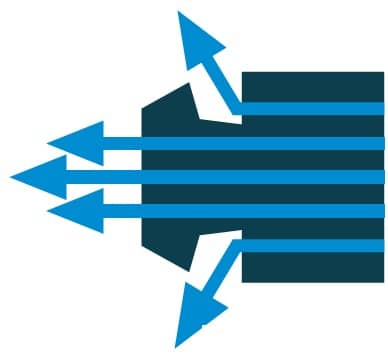

Injector nozzle

|

Special attachment using the Venturi effect (sucking ambient air into the stream). Thanks to the side openings, the injector nozzle draws in ambient air and mixes it with the flow from the compressor, thus significantly increasing the volume of the output air. The result is a much thicker and wider bang (the flow can be up to 2-3 times higher than the basic nozzle at the same pressure). Suitable for quick cleaning of larger areas, blowing large amounts of chips, dust, etc. - in short, when you need maximum blowing power. Note: Injector nozzles can be plastic (lighter) or metal (more durable), both variants work on the same principle. |

|

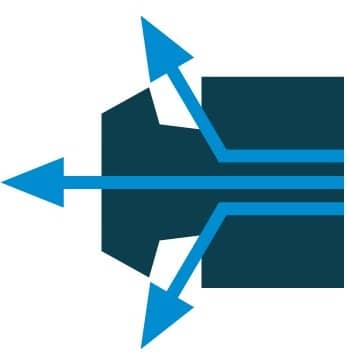

Nozzle with air shield

|

The so-called safety deflector nozzle creates a protective air shield in addition to the main jet. Special side openings or nozzle shapes direct some of the air into a circular "envelope" around the main jet. This air shield prevents dirt from flying towards the operator - small dust particles and dirt are blown by the jet around the nozzle and do not go directly into the eyes of the worker. These nozzles increase work safety, especially when blowing sharp metal sponges or dangerous dusts. The disadvantage is a slight reduction in main power and higher air consumption (some of it is "wasted" on the shield). |

|

Safety soundproof nozzle

|

It combines the advantages of a soundproof and safety nozzle. It is a modern safety nozzle that meets international standards (e.g. OSHA, BIA, BG, etc.), which reduces noise (approx. 74 dB) and at the same time creates a protective air shield. In addition, thanks to the conical air guide inside the nozzle, it also partially uses the injector effect to increase the blowing power (up to 2.5 times the power of a conventional nozzle). These nozzles are ideal in industries where health and safety is a priority - minimising the risk of injury and noise pollution. |

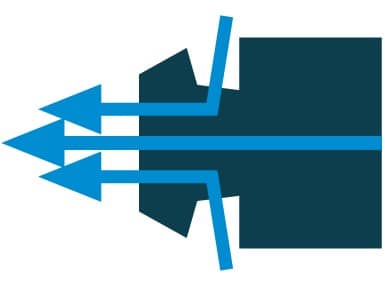

| Extended nozzle | Extended nozzles (straight or curved) are used for blowing hard-to-reach areas. These are long extensions (e.g. lengths of 100+ mm) made of metal that can be straight or slightly curved to reach "around the corner". The extended nozzle allows the air stream to reach deep into machines, pipes, boreholes, etc. It can also be used where you need to blow at a safe distance from each other (e.g. hot or dangerous objects). The disadvantages can be a slight drop in pressure at the outlet due to the length and the need to be careful with the long extension when handling. |

| Extended nozzle with protective tip | Variant of the extended nozzle, which has a protective rubber extension (rubber tip) at the end. This rubber cover protects the blown surface from scratches or mechanical damage in case the nozzle touches the material. It is ideal for blowing sensitive surfaces (e.g. polished parts, glass, painted parts) where a metal tube could leave scratches. |

Note: There are also other special nozzles on the market, such as flat wide nozzles (for offsetting large areas with a thin "knife" air stream) or brush nozzles (combining mechanical sweeping of dirt with bristles and offsetting at the same time). These are not yet in our standard offer, but we are considering their inclusion - see below.

Currently offered types of pistols and accessories

Our e-shop offers a comprehensive range of blow guns and related components. Currently in category Blow guns you can find for example:

- ABG Blow Gun - Quality metal gun (aluminium) suitable for industrial use. It is available in both short and extended versions (nozzle length up to 300 mm) and has the option of interchangeable nozzles. It is versatile for most applications.

- ABGP Blow Gun - Variant with plastic body (durable polyamide). A lightweight gun that doesn't get cold in the hand - ideal where temperatures are extreme or where a metal gun is not desirable. More suitable for medium duty and normal workshop use.

- BLP Blow Gun - Die-cast aluminium gun, robust construction with long service life. It belongs to the middle class - it offers a good price/performance ratio and is popular in garages and industry.

- Blow gun BG470 - Gun made of hardened polyamide (special hard plastic). It combines light weight and durability; suitable even for more demanding applications where conventional plastic might not be sufficient.

- Blow gun BG269L - Classic blow gun made of die-cast aluminium. Reliable design with fixed base nozzle, ideal for common blowing work in the workshop or industry.

- Blow Gun BG269A - Forged aluminium gun of the highest quality. Designed for the most demanding conditions, it can withstand rough handling and long-term operation.

- Blow Gun BG269E - Aluminium gun with flow control (model with integrated control element). It allows you to adjust the power of the blow directly on the gun, which is great for precision work or saving air.

- Interchangeable blowing nozzles M12×1,25 - Wide range of nozzles compatible with the above mentioned guns. We offer all the above mentioned types: basic, soundproof, injector, safety (with shield and combined), extended of different lengths and designs. These replacement nozzles allow you to expand the gun's capabilities to meet the exact needs of the application.

- BLP pressure regulators on the hose - Additional accessories: small regulators (pressure reducing valves) that are mounted between the gun and the supply hose. They maintain a set constant air output pressure to the gun regardless of fluctuations in the input pressure. They help to save compressed air and increase work safety (the selected pressure of the blowing agent cannot be exceeded).

Practical tips for safe and efficient blowing

Using blow guns is relatively simple, but for safety and efficiency, keep a few guidelines in mind:

- Protecting eyesight and health: Always wear safety glasses or a face shield when blowing. The airflow can pick up and eject dirt particles at high speed - preventing eye injuries is key. In the industry, earplugs or earphones are also mandatory, especially if you are not using soundproof nozzles. Never point the blowgun at yourself or others - compressed air can cause serious injury (air under the skin, hearing damage, etc.). Therefore, do not exceed the recommended pressure for blowing (usually up to 6 bar).

- Correct pressure and air saving: Set only the pressure you really need on the compressor or regulator. For most blowing, 4-6 bar is sufficient. Higher pressure means higher air consumption and noise, and it doesn't always give a better result - lower pressure is enough for fine dust, a strong jet would just stir it up unnecessarily in the surroundings. Save compressed air by using injector or multi-channel nozzles that increase the effect without the need for extreme pressure.

- Choosing the right nozzle: Match the nozzle to the task at hand. The narrow base nozzle is ideal for stubborn dirt in corners, while the injector nozzle blows a large area of fine dust away much faster. In noisy operations or where there are multiple people working around, consider using a soundproof or safety nozzle to reduce noise and the risk of injury from flying particles. Use the extended nozzles when you need to get into hard-to-reach places - but use them carefully so you don't damage anything with the long nozzle lever.

- Maintenance and inspection: Keep the gun and nozzle clean. When the work is finished, check for debris stuck in the nozzle orifice (it could affect the jet or shoot out unexpectedly later). Occasionally drip a drop of oil into the moving parts of the gun (if you don't have a maintenance-free gun) - especially the trigger joint and valve - to ensure smooth operation and long life. When replacing the nozzle, make sure that it is screwed into the gun correctly and firmly.

- ESD and sensitive electronics: if you are ventilating electronic components or working in an ESD-protected area, beware of static electricity. The airflow can create an electrostatic charge and damage sensitive chips. For this purpose, there are ESD variants of blow guns - made of conductive materials or with an ionization unit that eliminates the charge. Consider their use in the electrical industry (e.g. for cleaning computers, circuit boards, etc.).

Direction of the category - what are we planning and what to add?

Our range of blow guns and nozzles is already very wide, but we are not resting on our laurels. We are still monitoring the market development and demand and we plan to further expand the range so that there is a choice for everyone. In the future, we are considering adding or making more visible, for example, the following products:

- Extra long blow guns: For special applications, we prepare guns with extra long tubes (e.g. 500 mm or more). These models will be appreciated, for example, by maintainers of large machines when they need to blow very remote or hard-to-reach areas (high overhead, inside the machine, etc.) without having to use a ladder or dismantle the covers.

- Flexible nozzles: in addition to the extended nozzles, we also want to add flexible variants, i.e. flexible attachments that can be bent to the desired angle. These allow the airflow to be directed anywhere, for example around a corner of a pipe or into a cavity where a fixed pipe cannot reach. After blowing, the nozzle can be straightened or re-adjusted as required.

- Specially ergonomic pistols: For customers who use blow guns all shift, we are preparing more ergonomic models. These guns will have an improved handle shape for a more comfortable grip, an easy-to-walk trigger with optimum resistance, and possibly a hose swivel coupling and a hanging hook to allow the operator to put the gun at hand. The aim is to reduce hand fatigue and increase work safety (less risk of dropping the gun, etc.).

- ESD blow gun: As already mentioned, there is interest in the electrical industry for guns that do not cause electrostatic discharge. We plan to include ESD blow guns with conductive bodies and possibly ionization nozzles that are safe for blowing sensitive electronics and in environments where even a small discharge can cause damage.

- Flat and special nozzles: we would like to add flatter blowing nozzles to our range of nozzles, which create a wide flat air stream (suitable for blowing dust off wide panels or boards evenly, for example). These flat nozzles are often able to reduce noise and power consumption thanks to several parallel holes. We are also considering brush nozzles for combined mechanical and pneumatic cleaning.

We hope that this overview has helped you to find your way around the category of blow guns, guns and nozzles. Whether you're a DIYer or a representative of an industrial company, the right blow gun with the right nozzle will make your job easier, increase cleaning efficiency and ensure safer operation. Take a look at our current offer and don't hesitate to contact us if you have any questions - we will be happy to help you choose the ideal solution for your application.

-

ABG blow guns; short and extended

ABG blow guns; short and extended

-

ABGP blow gun; plastic version

ABGP blow gun; plastic version

-

BLP blow guns; cast aluminium

BLP blow guns; cast aluminium

-

Blow gun BG470; made of hardened polyamide

Blow gun BG470; made of hardened polyamide

-

Blow gun BG269L; cast aluminium

Blow gun BG269L; cast aluminium

-

Blow gun BG269A; made of forged aluminium

Blow gun BG269A; made of forged aluminium

-

Blow gun BG269E; with air flow adjustment

Blow gun BG269E; with air flow adjustment

-

Nozzles for blow guns; replacement nozzles M12x1,25

Nozzles for blow guns; replacement nozzles M12x1,25

-

BLP pressure regulators; constant outlet pressure

BLP pressure regulators; constant outlet pressure

Bestsellers

Curved long GNLB-260 nozzles with straight profiles for improved handling and reach during blowing. Nozzle length 260 mm.

Straight long nozzles GNL-265 with straight profile for improved handling and reach during blowing. Nozzle length 265 mm.