Measuring chamber sensor dewy point - BDRY-MK

Code: BDRY-MK

Related products

Product detailed description

Dew point sensor measuring chamber - for regeneration air saving - BDRY-MK

Operating cycles of BDRY adsorption dryers

B-DRY dryers can operate in two operating modes depending on the settings of the control unit.

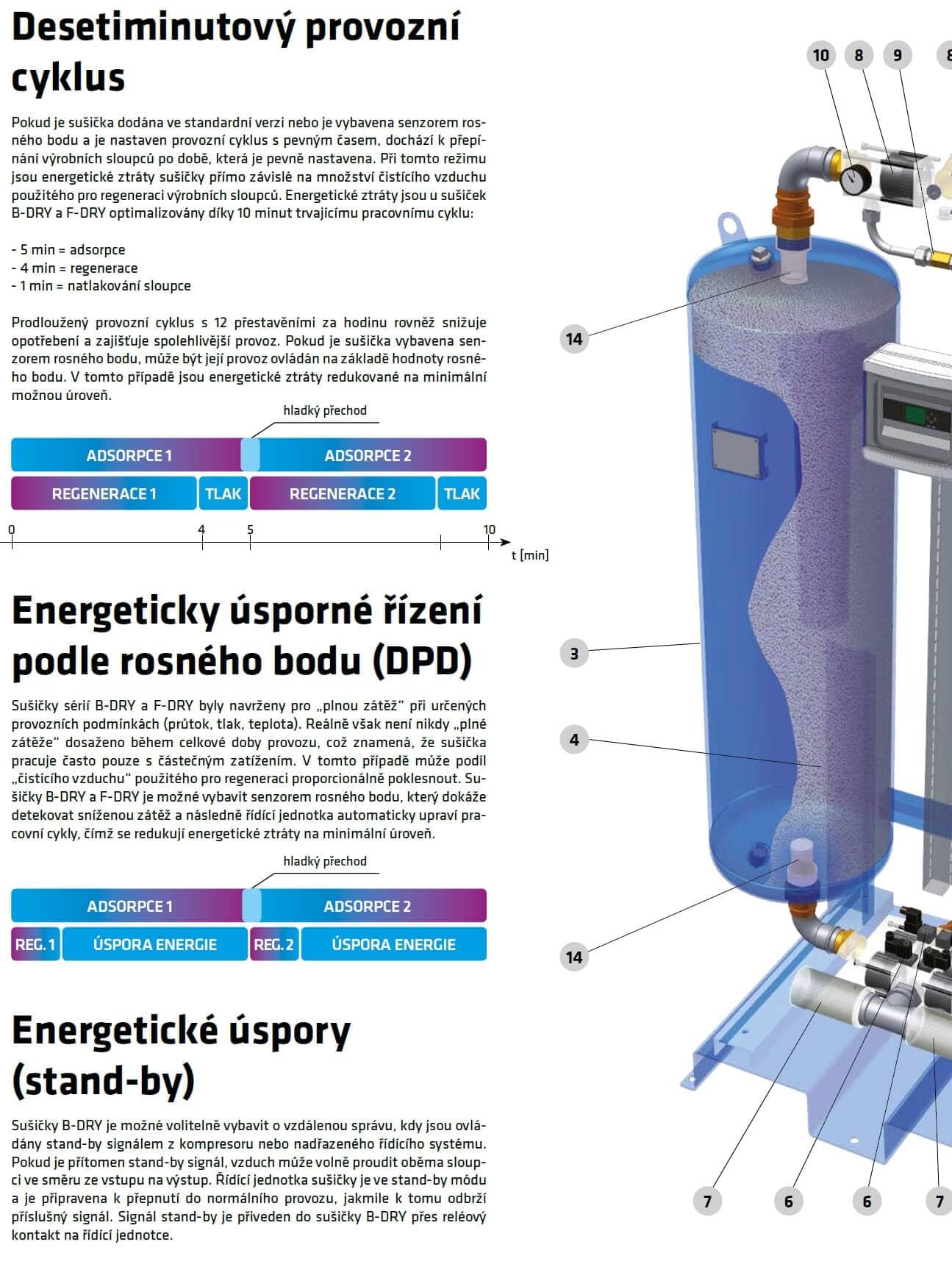

Ten-minute duty cycle

If the dryer is supplied in the standard version or equipped with a dew point sensor and a fixed time operating cycle is set, the production columns are switched after a fixed time. In this mode, the energy losses of the dryer are directly dependent on the amount of purge air used to regenerate the production columns. Energy losses are optimised in the B-DRY and F-DRY dryers thanks to a 10-minute duty cycle:

- 5 min = adsorption

- 4 min = regeneration

- 1 min = column pressurization

The extended duty cycle with 12 changeovers per hour also reduces wear and ensures more reliable operation. If the dryer is equipped with a dew point sensor

point, its operation can be controlled based on the dew point value. In this case, energy losses are reduced to the minimum possible level.

Energy-saving dew point control (DPD)

The B-DRY and F-DRY series dryers were designed for "full load" at specified operating conditions (flow, pressure, temperature). In reality, however, "full load" is never achieved during the total operating time, which means that the dryer often operates only with a partial load. In this case, the proportion of "cleaning air" used for regeneration may decrease proportionally. The B-DRY and F-DRY dryers can be equipped with a dew point sensor that can detect a reduced load and then the control unit automatically adjusts the operating cycles, reducing energy losses to a minimum level.

Energy savings (stand-by)

The B-DRY dryers can be optionally equipped with remote control, where they are controlled by a stand-by signal from the compressor or the master control system. If a stand-by signal is present, air can flow freely through both columns in the inlet to outlet direction. The dryer control unit is in stand-by mode and is ready to switch to normal operation as soon as it receives a signal to do so. The stand-by signal is fed to the B-DRY via a relay contact on the control unit.

Additional parameters

| Category: | Compressed Air Moisture Removal Air DryersAdsorption Compressed Air Dryer – Ultra-Dry Air for Demanding Applications |

|---|---|

| Dryer type: | Adsorption dryer |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Alfa and Omega from SloveniaIn the Slovenian capital, Ljubljana, there is a company specialized in compressed air treatment, production of industrial filters and filter inserts, separators or special membrane dryers and other products. Omega Air was founded in 1988 as a family business and soon secured a place in the industry. Over the years, Omega Air's workforce has also grown with increasing production and today the company employs more than 250 people. |

|

|

Omega products are used everywhereA wide range of applications is typical for Omega Air products. Its products are used in heavy industry as well as by private entities. Slovenia's footprint is thus noticeable in industrial sectors such as electrical, gastronomy, pharmaceuticals, moto and also in the chemical-industrial sector. However, the company's main product is special filters, which are exported all over the world. |

No greenhorn in the industryOmega Air also boasts several proprietary innovations and patents that originate in the development department. The company has also been awarded several times for its innovative solutions at the International Engineering Fair itself, which is traditionally held in Hannover, Germany. The Omega Air product range is brought to you by our air compressors company below. |

What Omega Air produces:

|