Membrane Compressed Air Dryer – Compact and Silent Drying Solution for Point-of-Use Applications

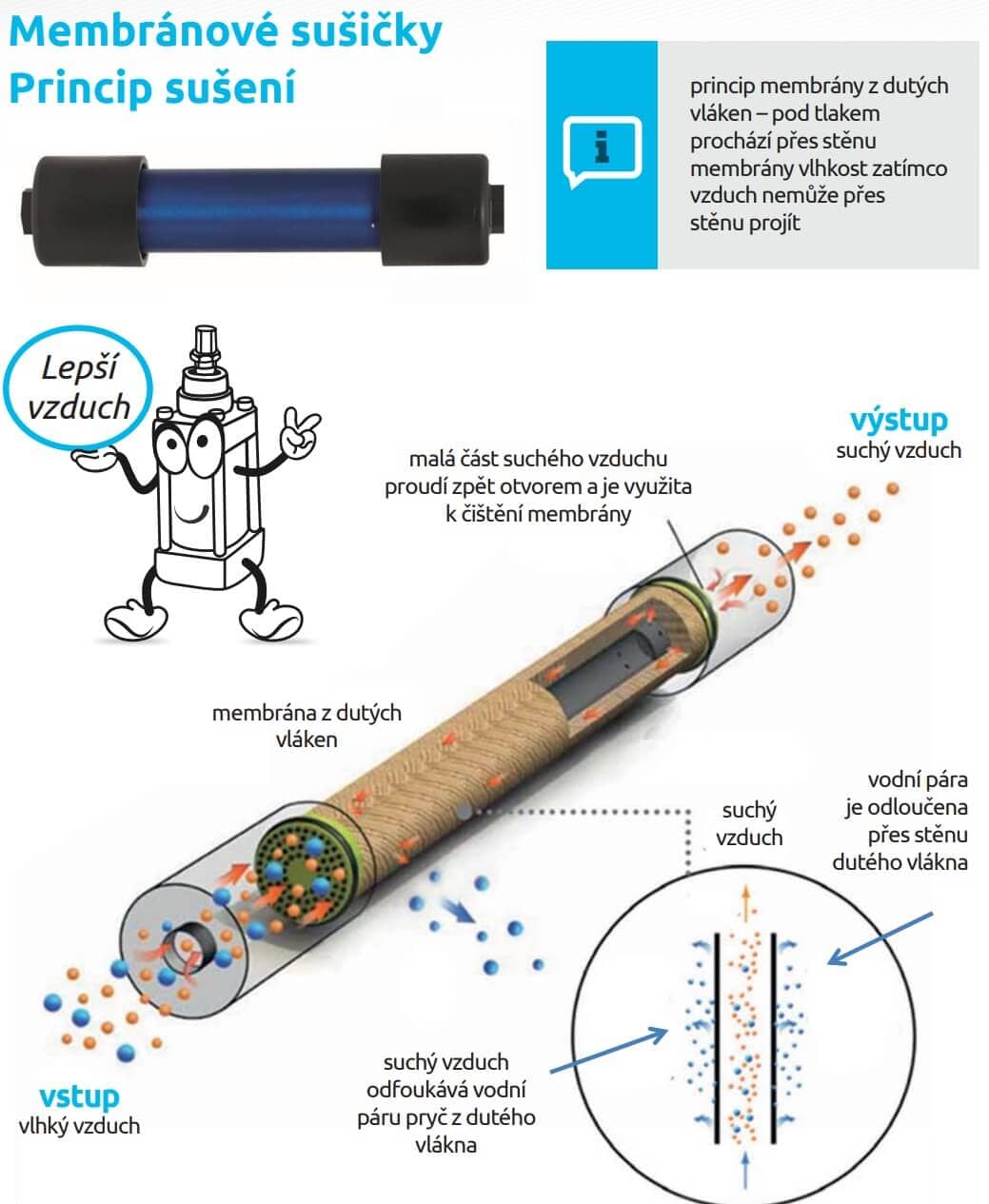

Membrane dryers offer a compact solution for air drying using semi-permeable membranes. Structurally, it’s a cylindrical cartridge housing a bundle of hundreds of hollow fibers forming the membrane. These fibers allow water vapor molecules to pass through their walls, while other gas components (dry air) are retained. When humid compressed air enters the membrane dryer, it flows through the fiber interiors toward the outlet. Due to concentration differences, water vapor penetrates the micropores of the membrane into the outer space. A small portion of the dry air is used as purge air flowing outside the fibers to carry away the extracted moisture through an exhaust port. The result is significantly drier air exiting the fibers. Membrane dryers can reduce the pressure dew point of air to approximately –20 °C to –40 °C, depending on purge flow and membrane length.

#ShowMore#

Advantages

- Very compact dimensions and low weight – membrane dryers are cartridge-shaped and easily fit into tight spaces or directly into the air distribution pipeline.

- Simple installation and operation: no moving parts, no electric components, and no power supply required – only the compressed air pressure itself.

- Silent operation and immediate readiness – no warm-up phase or switching cycles like in twin-tower adsorption dryers.

- Long membrane lifespan when used properly; ideal for continuous drying of small air volumes without operator intervention.

Disadvantages

- A portion of inlet air is consumed as purge flow (typically 10–20% of flow, or up to 30% for lowest dew points), reducing total usable air volume.

- Limited flow capacity: for higher air volumes, many membrane modules would need to be connected in parallel, making it expensive – other dryers are more economical for medium to large compressors.

- Lower drying performance compared to top-tier adsorption dryers – membranes typically don’t reach extreme dew points (below –40 °C) as effectively as desiccant-based systems.

- Sensitive to contamination: to prevent damage or clogging of the membrane fibers, high-quality air filtration is essential (dirt and oil aerosols could permanently impair the membrane).

Applications

Membrane air dryers are ideal for small-scale applications and point-of-use drying where dry air is needed but flow rates are low. Common in laboratories, medical or analytical devices, precision pneumatic tools, or in ATEX zones where electrical components are undesirable. Thanks to their compact design, they can be mounted directly next to machines or processes – e.g., packaging lines, optical instruments, dosing equipment, or robotic stations requiring consistent dry air. They are also useful in mobile compressor sets and service vans where no electric power is available for refrigerated or adsorption dryers.

Comparison with Other Dryer Types

Compared to other dryers, membrane units are unique in their simplicity and purpose. Unlike refrigerated dryers, they require no electricity and achieve lower dew points, but for higher air volumes, refrigeration is far more efficient (membranes are suited for flows too small for effective cooling). Compared to adsorption dryers, membranes offer lower initial cost and simpler operation for small flows, though they can’t achieve the same ultra-low dew points or handle large volumes. Membrane dryers are a good alternative to small adsorption units where a dew point of –20 °C to –40 °C is sufficient and maintenance must be minimized. To maximize air quality, an additional filter can be installed downstream – such as an activated carbon column to remove any remaining oil vapors, similar to other systems.

Reminder: Membrane dryers require very clean inlet air to function correctly. Always install a proper compressed air filter beforehand – ideally a combination of coalescing and fine particle filters. This ensures the membrane's declared lifespan and stable dew point performance. Also, be aware that a small amount of air will be vented to the atmosphere behind the membrane dryer as moisture carrier.

-

RDP condensation dryers; pressure dew point +3 °C

RDP condensation dryers; pressure dew point +3 °C

-

.jpg) Condensation dryers WDF; dew point +3°C with filters

Condensation dryers WDF; dew point +3°C with filters

-

-hankison-susicka-vzduch-kompresor-tllak-kondenzace-rosny-bod.jpg) HDI air dryers; pressure dew point +4°C

HDI air dryers; pressure dew point +4°C

-

RDL condensing dryers; pressure dew point +5°C

RDL condensing dryers; pressure dew point +5°C

-

Cool air dryers; pressure dew point +5°C

Cool air dryers; pressure dew point +5°C

-

MDX air dryers; pressure dew point +3°C

MDX air dryers; pressure dew point +3°C

-

.jpg) ADRY air dryers; smaller adsorption -40°C

ADRY air dryers; smaller adsorption -40°C

-

BDRY air dryers; large adsorption -40°C

BDRY air dryers; large adsorption -40°C

-

MADRY air dryers; membrane -40°C

MADRY air dryers; membrane -40°C

-

Activated carbon columns; activated carbon separation

Activated carbon columns; activated carbon separation

MADRY-6 membrane dryer with compressed air flow up to 6 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-12 membrane dryer with compressed air flow up to 12 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-123 membrane dryer with compressed air flow up to 123 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to...

MADRY-18 membrane dryer with compressed air flow up to 18 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-180 membrane dryer with compressed air flow up to 180 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to...

MADRY-24 membrane dryer with compressed air flow up to 24 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-3 membrane dryer with compressed air flow up to 3 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-32 membrane dryer with compressed air flow up to 32 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-44 membrane dryer with compressed air flow up to 48 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-63 membrane dryer with compressed air flow up to 63 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-9 membrane dryer with compressed air flow up to 9 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

MADRY-90 membrane dryer with compressed air flow up to 90 m³/hr up to 12 bar. Including 2 filters through the dryer and filter cartridge clogging indication. Designed to supply...

Replacement diaphragm for MADRY-12M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-123M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-3M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-180M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-24M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-44M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-63M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-18M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-32M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-6M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-90M compressed air dryer from compressor working on the principle of water separation by means of hollow fibre diaphragm.

Replacement diaphragm for MADRY-9M compressed air compressor membrane dryer working on the principle of water separation using a hollow fibre membrane.