Condensation pressure dryer WDF-23

Code: WDF-23

Product detailed description

Condensing air dryer WDF-23 - dry and clean air from the compressor

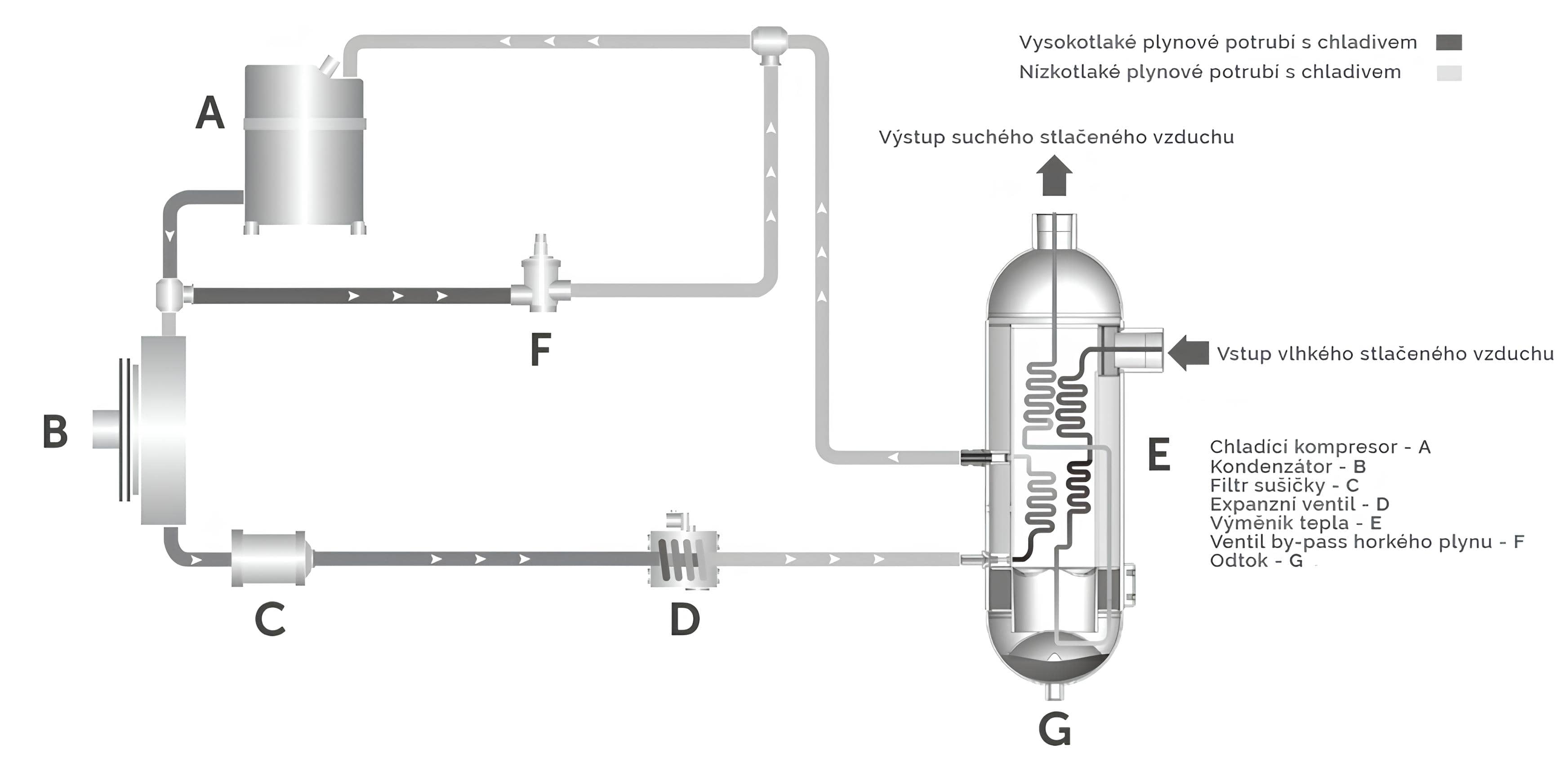

The WDF-23 is a powerful condensing air dryer designed for efficient drying of compressed air in smaller compressor systems. It uses the cooling principle: hot, moist air from the compressor passes through a cooling exchanger where it cools and the water vapour condenses. The condensate is then automatically drained out of the dryer using the integrated automatic condensate drain, so the operator does not have to manually drain the trapped water. The result is dry air with a pressure dew point of up to +3 °C, which reliably prevents corrosion, damage to pneumatic components and moisture-induced paint defects.

Technical specifications – WDF-23:

- Air flow: 23 m³/h (0.38 m³/min) - suitable for compressors with an output of ~380 l/min.

- Pressure dew point: +3 °C - dry air for quality results and equipment protection.

- Working pressure: 4 to 16 bar - wide range for use with most compressors.

- Air connection: G 1/2" male thread - easy installation into existing ductwork.

- Filtration system: built-in pre-filter 1 µm + filter 0.01 µm - removal of solid particles, oil mist and impurities.

- Refrigerant: R134a - environmentally friendly refrigerant for efficient and safe operation.

- Power supply: 230 V / 50 Hz (single phase) - can be connected to the mains.

- Power consumption: low, economical operation (small refrigerant compressor with economical energy consumption).

- Noise: Low - quiet operation without disturbing the operator (comparable to a normal household appliance).

- Weight: 32 kg - light and portable, easy to handle during installation.

- Dimensions (l × w × h): 420 × 360 × 560 mm - compact design saves space in the workshop.

The main advantages of the WDF-23:

-

Two-stage filtration - The dryer has two integrated filters (1 µm coarse and 0.01 µm fine) that capture dust, rust, oil aerosols and other impurities. This guarantees a clean air supply and protects the dryer itself and downstream equipment (air ducts, valves, tools) from dirt clogging. No need to buy external filters - everything is already built-in, saving costs and space.

-

High drying efficiency - The WDF-23 reliably reduces the humidity in the air to a pressure dew point of +3 °C. This dried air will prevent condensation in the piping and end applications. Your pneumatic tools, paint guns or machines will be protected from water that would otherwise cause corrosion, malfunctions or product degradation (e.g. paint surface defects).

-

Low pressure drop - The design of the dryer minimizes the drop in air pressure when passing through the dryer (pressure drop of approx. 0.15-0.22 bar at full flow). As a result, the performance of your pneumatic system is not significantly reduced and the compressor does not have to run at higher speeds, saving energy and extending its service life.

-

Compact and robust design - The WDF-23 features a robust construction made of high-quality materials that guarantee a long service life even in continuous operation. The unit is compact, so you can easily place it in smaller areas of the compressor station or workshop. The corrosion-resistant copper/aluminium heat exchanger and robust brass connections ensure reliable operation at high loads and elevated inlet air temperatures.

-

Quiet and automatic operation - Thanks to the modern refrigeration circuit with a small compressor and a high-quality fan, the WDF-23 has a low noise level, which is especially appreciated in smaller operations where the dryer is located close to the workplace. The integrated automatic condensate drain continuously discharges the collected water without the need for operator intervention. The dryer can run continuously and carefree in the background - just switch it on and it takes care of everything. A simple control panel (LED indicators) gives you an overview of the status of the appliance and any alerts, so you have control over the correct operation of the dryer.

-

Cost savings and easy maintenance - Using the WDF-23 dryer will significantly extend the life of your compressor and tools, as the dry air prevents corrosion of tanks and pneumatic systems. Lower operating costs are ensured by both energy savings (due to low pressure drop) and minimal maintenance requirements. The dryer only requires occasional checking of the filter cartridges and the cooling circuit. Built-in filters with automatic dirt removal make servicing easy - condensate and trapped particles are automatically removed, so maintenance is quick and clean.

Practical use: the WDF-23 condensation dryer can be used in a wide range of applications. With a flow rate of 23 m³/h, it is ideal for smaller and medium-sized compressors in car repair shops, tire shops, carpentry and locksmith shops or smaller industrial plants. It is suitable wherever well-dried compressed air is needed - for example, for driving pneumatic tools (tighteners, spray guns, blow guns), in paint and powder coating booths (where moisture adversely affects the quality of the paint), for protecting sensitive pneumatic cylinders and valves in automated lines, or for laboratory and medical instruments requiring clean dry air. The WDF-23 is easy to connect to your air handling system - usually installed after the compressor and before the pressure vessel or air distribution. With its compact dimensions and quiet operation, it can be placed directly in the work area. This dryer thus contributes to higher reliability, efficiency and quality of production in your company.

Additional parameters

| Category: | Compressed Air Moisture Removal Air Dryers |

|---|---|

| Pressure: | 16 bar |

| Connecting: | 1/2" |

| Motor power: | 340 W |

| Mains voltage: | 230 V |

| Noise: | 45 dB(A) |

| Condensate discharge: | Automatic, Electronic |

| Flow: | 333 l/min |

| Equipment:: | Control unit LED display, Automatic draining of condensate |

| Refrigerant: | Refrigerant R134a |

| Pressure dew point: | +3 °C |

| Dryer type: | Condensation dryer |

| Pressure: | 16 bar |

| Dimensions: | 370 x 372 x 706 mm |

| Weight: | 32 kg |

| Integrated pre-filter: | 1 um |

| Integrated microfilter: | 0.01 µm |

| Pressure drop: | 115 mbar |

| Connecting: | 1/2" |

| Motor power: | 340 W |

| Mains voltage: | 230 V |

| Noise: | 45 dB(A) |

| Condensate discharge: | Electronic |

| Flow: | 333 l/min |

| Equipment:: | Automatic draining of condensate |

| Refrigerant: | Refrigerant R134a |

| Pressure dew point: | +3 °C |

| Dryer type: | Condensation dryer |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

WALTER Kompressortechnik - Innovative Solutions for Compressors

- About the company WALTER: WALTER Kompressortechnik is a renowned manufacturer of air compressors and accessories, known for its quality, reliability and innovative technologies. The company focuses on providing highly efficient solutions for various industries.

- Product portfolio:

- Screw compressors: we offer a wide range of screw compressors that are designed for maximum energy efficiency and long life. Ideal for high demanding industrial applications.

- Reciprocating compressors: these compressors are robust and reliable, suitable for smaller applications and workshops where high flexibility and low running costs are required.

- Mobile compressors: lightweight and easily portable compressors that allow easy use in a variety of locations, ideal for construction and field work.

- Scroll and special compressors: provide quiet operation and are suitable for specific applications requiring minimal vibration and noise.

- Innovation and quality: WALTER emphasizes continuous development and improvement of its products to ensure maximum customer satisfaction. Their compressors are equipped with advanced technologies to optimise performance and save energy.

- Customer support and service: the company offers comprehensive service, including installation, maintenance and diagnostics, ensuring the long-term reliability and efficiency of their equipment.