WDF condensation dryers - quiet operation with integrated filters

The WDF series of condensing (refrigeration) air dryers from Walter Kompressortechnik are the ultimate solution for compressed air treatment. They are designed to remove moisture from the air highly efficiently and at the same time with minimal pressure loss. Thanks to built-in filters, they deliver not only dry but also clean air free of dirt and oil aerosols, protecting your equipment and extending its life. Below we will take a closer look at the main features, specifications and technology of WDF dryers, compare them with other types of dryers and give you reasons why you should buy from us.

Specific features and advantages of WDF dryers

.jpg) |

|

WDF condensation dryers with integrated filters |

||||||||||||

| Ordering number |

Flow | Pressure Bar |

Voltage V/Hz |

Power consumption | Pressure fallout |

Connection " |

Dimensions mm | Weight kg |

Refrigerant | |||

| m³/h | l/min | kW | mbar | d | with | in | ||||||

| WDF-23 | 23 | 383 | 16 | 230/50 | 0,34 | 115 | 1/2" | 370 | 372 | 706 | 32 | R134A |

| WDF-38 | 38 | 633 | 16 | 230/50 | 0,34 | 170 | 1/2" | 370 | 372 | 706 | 32 | R134A |

| WDF-53 | 53 | 883 | 16 | 230/50 | 0,37 | 280 | 1/2" | 370 | 372 | 706 | 32 | R134A |

| WDF-70 | 70 | 1 166 | 16 | 230/50 | 0,38 | 250 | 1/2" | 370 | 372 | 706 | 35 | R134A |

| WDF-100 | 100 | 1 666 | 16 | 230/50 | 0,39 | 100 | 3/4" | 473 | 453 | 832 | 51 | R134A |

| WDF-155 | 155 | 2 583 | 16 | 230/50 | 0,59 | 220 | 3/4" | 473 | 453 | 832 | 53 | R134A |

| WDF-190 | 190 | 3 166 | 16 | 230/50 | 0,68 | 320 | 3/4" | 473 | 453 | 832 | 55 | R134A |

| WDF-210 | 210 | 3 500 | 16 | 230/50 | 0,82 | 220 | 1 1/2" | 553 | 503 | 874 | 78 | R134A |

| WDF-305 | 305 | 5 083 | 16 | 230/50 | 1,07 | 320 | 1 1/2" | 553 | 503 | 874 | 83 | R134A |

| WDF-375 | 375 | 6 250 | 16 | 230/50 | 1,19 | 200 | 1 1/2" | 553 | 503 | 874 | 86 | R134A |

| WDF-495 | 495 | 8 250 | 16 | 230/50 | 1,23 | 310 | 2" | 678 | 648 | 1 157 | 160 | R134A |

| WDF-623 | 623 | 10 383 | 16 | 230/50 | 1,32 | 240 | 2" | 678 | 648 | 1 157 | 165 | R134A |

| WDF-930 | 930 | 15 500 | 16 | 230/50 | 2,01 | 150 | 2" | 948 | 728 | 1 370 | 220 | R134A |

| WDF-1200 | 1 200 | 20 000 | 16 | 230/50 | 2,59 | 190 | 2" | 948 | 728 | 1 370 | 230 | R134A |

| WDF-1388 | 1 388 | 23 133 | 16 | 400/50 | 2,80 | 350 | 3" | 948 | 798 | 1 460 | 270 | R134A |

| WDF-1800 | 1 800 | 30 000 | 16 | 400/50 | 3,21 | 290 | 3" | 948 | 798 | 1 460 | 285 | R134A |

| WDF-2500 | 2 500 | 41 666 | 16 | 400/50 | 4,10 | 150 | 3" | 1 163 | 778 | 1 725 | 392 | R134A |

| WDF-2775 | 2 775 | 46 250 | 16 | 400/50 | 4,74 | 350 | 3" | 1 163 | 778 | 1 725 | 410 | R134A |

| WDF-3330 | 3 330 | 55 500 | 16 | 400/50 | 270 | DN 100 | 1 577 | 993 | 1 906 | 492 | R134A | |

| WDF-3915 | 3 915 | 65 250 | 16 | 400/50 | 380 | DN 100 | 1 577 | 993 | 1 906 | 520 | R134A | |

| WDF-5085 | 5 085 | 84 750 | 16 | 400/50 | 320 | DN 100 | 1 647 | 1 077 | 2 005 | 696 | R134A | |

| WDF-5850 | 5 850 | 97 500 | 16 | 400/50 | 350 | DN 100 | 1 647 | 1 077 | 2 005 | 718 | R134A | |

| Reference flow measurement conditions: ambient temperature +25 °C, medium temperature +35 °C, working pressure 7 bar, dew point +3 °C ± 1 °C. | ||||||||||||

Correction factor - Working pressure |

|||||||||||||||

| Working pressure bar | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Correction factor | 0,70 | 0,80 | 0,87 | 0,92 | 0,96 | 1 | 1,03 | 1,05 | 1,07 | 1,08 | 1,10 | 1,11 | 1,12 | 1,13 | 1,14 |

#ShowMore#

Technical parameters of the WDF series

The WDF model range covers a wide range of performance, so there is something for everyone from the small workshop to the large industrial plant. Basic technical data of the WDF series:

- Air flow range: Models WDF 23 to WDF 2775 can handle volume flow rates from approximately 23 m³/h ( approx. 380 l/min) for the smallest model to 2775 m³/h ( approx. 46,250 l/min) for the largest. This allows the dryer to be sized to the exact capacity of the compressor.

- Pressure dew point: WDF condensing dryers achieve a standard dew point of +3 °C at pressure, a value that ensures very dry air suitable for most applications. This parameter is constant across models - even the largest dryers can keep the outlet air at a dew point of around 3°C.

- Operating pressure: The design of the dryers is rated for operating pressures between 4 and 16 bar. The dryers thus operate safely at normal compressed air distribution pressures (typically 6-10 bar) and can also handle higher pressures, for example up to 14-16 bar, without compromising function.

- Power supply: the smaller models (WDF 23 to approx. WDF 623) are single-phase with 230 V/50 Hz power supply, while the larger units (from WDF 930 upwards) require a three-phase 400 V/50 Hz power supply due to the higher power input of the refrigeration compressor. The input power ranges from around 0.3 kW for the smallest to several kW for the largest models.

- Connections and dimensions: depending on the flow rate, the corresponding inlet/outlet connections are fitted from 1/2" for small dryers to 2" DN50 for the largest dryers. This is matched by size and weight - compact models weigh tens of kilograms and fit under a desk, while industrial models can weigh hundreds of kilograms and require a fixed location. However, they all have a robust frame and cover to protect the components.

- Refrigerant and ecology: the WDF dryers use modern refrigerants (typically R134a in smaller models) in a closed circuit. The refrigeration circuit is designed to be reliable and environmentally friendly - minimising refrigerant leaks and fully compliant with current regulations.

Operating conditions: For optimum function, the maximum recommended ambient temperature is +50 °C and the minimum ambient temperature is +4 °C. The maximum inlet temperature of the compressed air to the dryer is +60 °C - at higher inlet temperatures it is advisable to include an aftercooler in front of the dryer. In this range of conditions, WDF dryers provide stable performance according to the specified parameters.

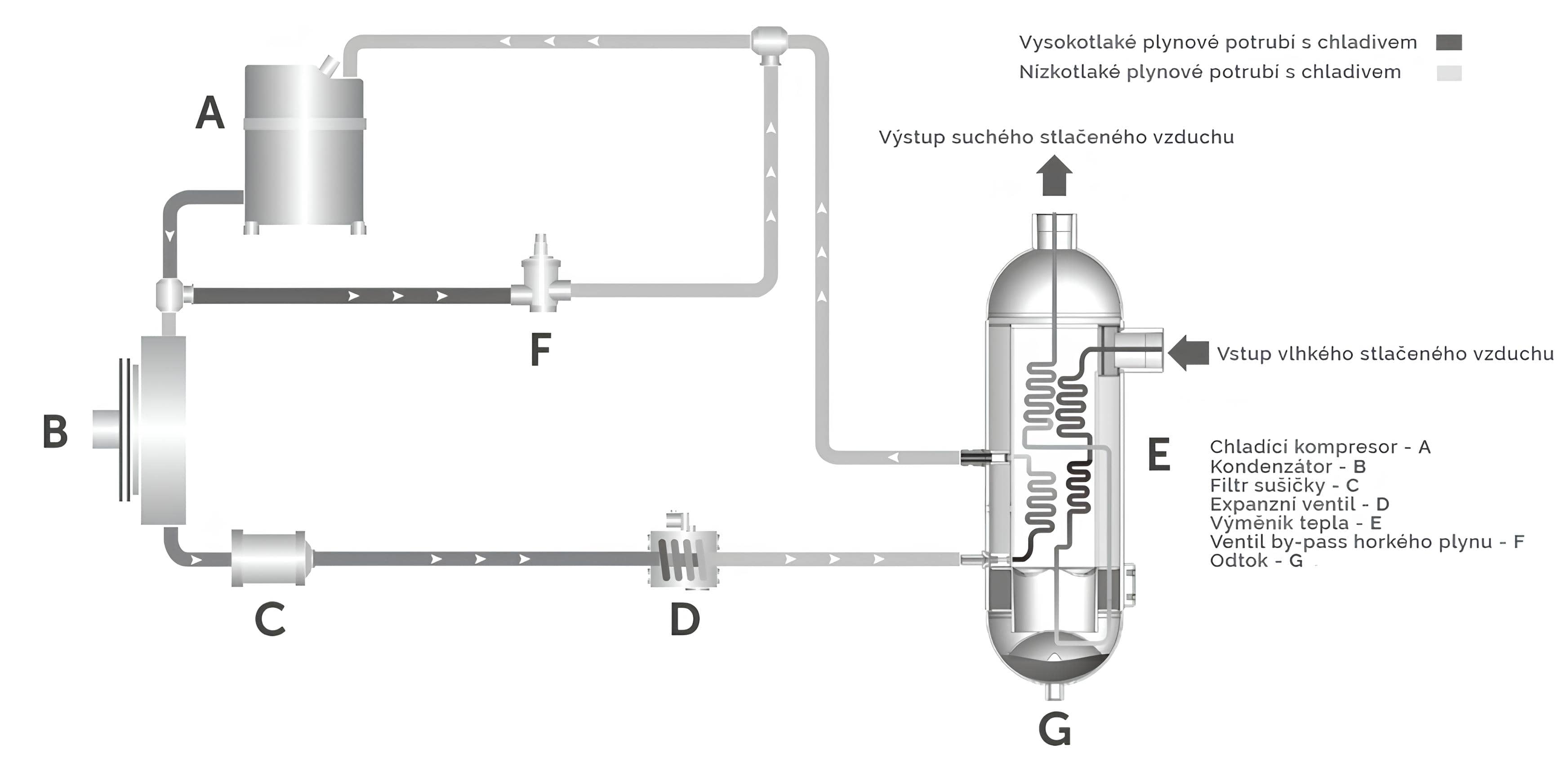

Features and technology of WDF dryers

Condensation drying principle: The WDF dryer works on the proven principle of compressed air cooling. The hot, humid air from the compressor first passes through a heat exchanger, where it is cooled by the refrigerant (compressor refrigerant circuit) to a temperature close to 0 °C. This precipitates (condenses) the water in the form of condensate. The resulting condensate is then automatically drained away using a drainage system (an electronic condensate drain ensures that the water drains away and does not return to the system). The dried cold air is then heated back up (by a counter-current exchanger) to almost the original temperature, so that moisture does not condense on the ducts - so at the dryer outlet you get dry air at a temperature close to the ambient temperature.

Digi-Pro electronic unit: at the heart of WDF technology is the Digi-Pro digital control unit, which monitors the operation of the dryer. It maintains the optimum cooling temperature to achieve the desired dew point of +3 °C without unnecessary overcooling (this saves energy). At the same time, it monitors the dryer's condition - it can display the heat exchanger temperature in real time or warn of excessive condensate, for example. In the event of deviations (e.g. temperature rise above normal, filter clogging or fan failure), the unit warns the operator with a light or alarm on the display. This helps to prevent faults before they occur. The Digi-Pro also makes it easy to switch the dryer on/off and reset it after servicing.

Integrated air filtration: As already mentioned, two integrated filters are a unique feature of WDF dryers. The first (inlet) filter removes larger dirt, particulates and oil droplets up to 1 micrometer in size from the compressed air, protecting the dryer itself and increasing cooling efficiency. The second (outlet) filter is a highly efficient coalescing filter that removes even the finest particles and oil aerosols down to 0.01 µm - the resulting air is not only dry, but also highly clean (air quality class 1 according to ISO 8573-1). This level of filtration normally requires separate filter units, but the WDF contains them in one compact unit. The filters are easily accessible for replacement and the control system monitors their condition - alerting you when they are due for maintenance, which is usually after about 12 months of operation (depending on load).

.jpg) |

|

|

Automatic operation and safety: the WDF dryers are designed for continuous operation with minimal operator requirements. Once installed and set up, they work automatically - maintaining the set drying parameters. The condensate drainage is automatic; the operator only occasionally checks if the condensate drainage is working (e.g. if the drain is not blocked). The units have built-in safety features such as a pressure switch and relief valve in the refrigeration circuit to prevent overrun, and electrical protection against compressor or fan overload. All of this contributes to a long service life and safe operation. Maintenance is thus limited to regular filter changes and occasional checking of the cleanliness of the condensers/coolers (so that they are not clogged with dust).

All in all, the combination of advanced cooling technology, intelligent control and integrated filtration makes WDF dryers a comprehensive device that significantly improves compressed air quality and makes compressor station operation more efficient.

Comparison with other air dryers

When selecting a dryer, it is a good idea to understand the differences between the WDF condensing dryers and other available technologies or models:

-

WDF vs. other condensing dryers: compared to conventional condensing dryers from other manufacturers, the WDF offers several advantages. First and foremost are the aforementioned integrated filters - competing dryers often require the installation of an external pre-filter (to remove oil and dirt before entering the dryer) and a micro-filter behind the dryer to ensure the air meets high purity requirements. With WDF, all this is handled in one device, saving you the initial investment, space and the hassle of additional accessories. The pressure drop is also significantly lower with WDF than some competing systems - this means that there is no noticeable pressure drop in the circuit when a WDF dryer is fitted, whereas less advanced dryers can cause a higher pressure drop (which the compressor then has to compensate for with higher output). The Digi-Pro control unit is a modern feature that may not be available on cheaper models (which may only have a simple thermostat without the ability to signal service needs). Plus, the Walter brand means reliable service and parts availability - after-sales service can be complicated with noname dryers. Overall, the WDF offers a more comprehensive and user-friendly solution compared to conventional air dryers.

-

Condensation vs. adsorption dryers: the WDF condensation dryers reach a dew point of around +3 °C, which suits most industrial applications (prevents condensation in pipes and tools at normal temperatures above freezing). Adsorption dryers use a different principle (moisture absorption by the desiccant) and can reach dew points down to -40 °C or lower. Such dry air is required, for example, in applications where pipes run in freezing temperatures or in industries such as food processing, pharmaceuticals or when painting really sensitive surfaces. However, extremely dry air comes at a higher price - adsorption dryers are more costly to operate (often consuming some of the compressed air for charge regeneration, thus reducing the overall efficiency of the system) and require regular replacement or drying of the adsorption charge. For standard use, the WDF condensing dryer is a more economical choice - it costs less to run (no air flushing, lower power consumption) and maintenance is easier (no drying charge, just filters and routine servicing of the cooling circuit). If you don't need an extremely low dew point, the WDF will provide the optimum performance-to-cost ratio.

-

Comparison of investment and operating costs: compared to the combination of a stand-alone dryer + external filters, the WDF is also advantageous. An integrated solution means you get one device instead of three, with one control system and one connection to the mains. This reduces not only the initial investment but also the installation costs (fewer pipe connections, fewer brackets, etc.). Lower pressure drop and intelligent control translates into lower operating costs - the compressor doesn't consume as much extra energy and filters are changed in a timely manner rather than increasing resistance. In the long run, WDF dryers save money compared to less efficient solutions.

Why buy a WDF dryer at Kompresory-vzduchotechnika.cz

By choosing and purchasing a WDF condensation dryer from us, you will receive a range of benefits and professional support:

- Lowest price guarantee: We offer very competitive prices and monitor the market to supply you with WDF dryers at the best possible price. If you find the same product cheaper, please contact us - we can match the price.

- Extended warranty and service: We offer a standard 2-year warranty on all WDF dryers, and even an extended warranty beyond the statutory period on selected models. We believe in the quality of the Walter brand, so we are not afraid to extend the warranty. At the same time, we provide warranty and post-warranty service - our technicians are trained to maintain this equipment and we can arrange any repairs or regular inspections.

- Expert advice: our team can help you choose the right dryer for your compressor and operation. You can take advantage of telephone or online consultation, we can advise you on flow sizing, connection of the dryer to the system and subsequent maintenance. Your satisfaction and the correct functioning of the equipment are our priority.

- In stock and fast delivery: we keep the most popular WDF models in stock so that we can dispatch them quickly. For others, we can arrange fast delivery from the manufacturer. In addition, when you order more than 10,000 CZK excluding VAT from us, you get free shipping to you - we will deliver heavier industrial dryers reliably and safely.

- Wide range of accessories: compressors-air-technique.cz is not just a retailer - we are specialists in compressed air. We have all the necessary accessories and spare parts for WDF dryers (filter inserts, condensate drainers, piping components, etc.). All in one place, so you can get your system up and running immediately and keep it in perfect condition.

- Verified Supplier: Our company prides itself on customer satisfaction, as evidenced by the number of positive reviews and awards (we hold a certificate "Verified by customers" on Heureka.cz, etc.). You are buying from a proven retailer that has been on the market for many years - you definitely won't go wrong with us.

In conclusion: the WDF condensing dryers are the ideal choice for anyone who wants reliably dried and clean compressed air with minimum fuss. Their quiet operation, integrated filters and high drying efficiency make them among the best on the market. Choose the model that suits your needs and put yourself in the hands of the experts at Kompresory-vzduchotechnika.cz - we will be happy to provide you with trouble-free delivery, commissioning and long-term support. With our WDF services and dryers, your compressed air system will run like clockwork - free of water, dirt and unnecessary downtime. See for yourself the quality of WDF and enjoy dry air for your business!

Bestsellers

The WDF-70 condensing air dryer provides efficient moisture removal from compressed air with a flow rate of 70 m³/h (1,166 l/min) and a pressure dew point of +3 °C. Thanks to...

The WDF-100 condensing air dryer provides efficient compressed air drying with a flow rate of 100 m³/h (1 667 l/min) and a pressure dew point of +3 °C. Integrated filters of 1...

The WDF-155 condensing air dryer effectively removes moisture from compressed air and achieves a pressure dew point of +3 °C. With a flow rate of 155 m³/h (2 583 l/min), it is...

The WDF-53 condensing air dryer efficiently removes moisture at a flow rate of 53 m³/h (883 l/min) and reaches a dew point of +3 °C. Integrated 1 µm and 0.01 µm filters ensure...

The WDF-190 condensing air dryer ensures efficient moisture removal from compressed air with a flow rate of 190 m³/h (3,166 l/min) and a pressure dew point of +3 °C. Thanks to...

The WDF-23 condensing (refrigeration) compressed air dryer with a capacity of 333 l/min up to 16 bar ensures reliable removal of moisture from compressed air up to a pressure...

The WDF-1200 condensing air dryer provides high-capacity compressed air drying with a flow rate of 1,200 m³/h (20,000 l/min) and a pressure dew point of +3 °C. Integrated...

The WDF-1388 condensing air dryer provides highly efficient compressed air drying with a flow rate of 1,388 m³/h (23,133 l/min) and a pressure dew point of +3 °C. Thanks to the...

The WDF-1800 condensing air dryer provides high-capacity compressed air drying with a flow rate of 1,800 m³/h (30,000 l/min) and a pressure dew point of +3 °C. Integrated...

The WDF-210 condensing air dryer provides highly efficient compressed air drying with a flow rate of 210 m³/h (3,500 l/min) and a pressure dew point of +3 °C. Integrated filters...

The WDF-305 condensing air dryer effectively removes moisture from compressed air at a flow rate of 305 m³/h (5,083 l/min) and achieves a pressure dew point of +3 °C. The...

The WDF-385 condensing air dryer efficiently removes moisture from compressed air at a flow rate of 385 m³/h (6,416 l/min) and achieves a pressure dew point of +3 °C. Integrated...

The WDF-38 condensing (refrigeration) compressed air dryer with a capacity of 633 l/min up to 16 bar ensures reliable removal of moisture from compressed air up to a pressure...

The WDF-495 condensing air dryer provides high-capacity compressed air drying with a flow rate of 495 m³/h (8,250 l/min) and a pressure dew point of +3 °C. Integrated filters (1...

The WDF-623 condensing air dryer effectively removes moisture from compressed air at a flow rate of 623 m³/h (10,383 l/min) and achieves a pressure dew point of +3 °C....

The WDF-930 condensing air dryer provides high-capacity compressed air drying with a flow rate of 930 m³/h (15,500 l/min) and a pressure dew point of +3 °C. Integrated filters...