Product detailed description

VIPD G2 double-acting axial valve"

- connecting thread G2"

- clearance DN 10

- working pressure 10 bar

- temperature up to +80°C

- material brass

- NBR seal

FUNCTION DESCRIPTION

|

| VIP valves have the actuator built into the valve body. The moving piston is driven by air. The piston will seat if it moves in the direction of the media flow. This stops the media flow. The seat is perfectly tight. The pressure required to move the piston is independent of the media pressure. The resulting VIP valve therefore saves space and the full flow ensures minimal pressure loss. |

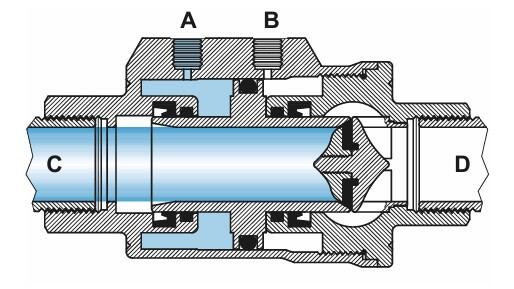

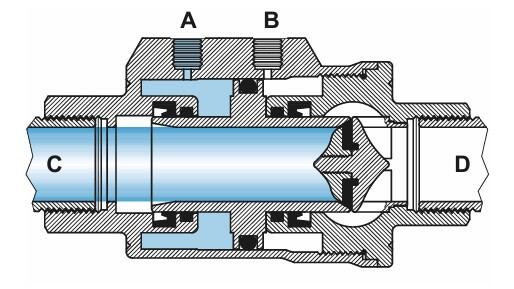

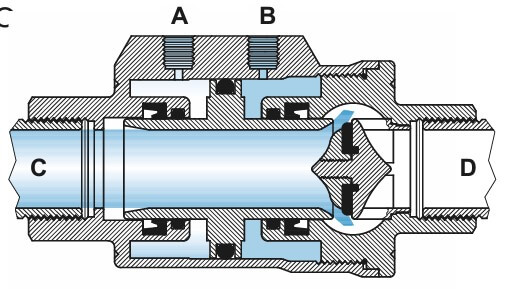

Closed valve

|

| When compressed air is supplied to bore A (bore B must be relieved), the piston seats and the valve is closed. In the case of the single-acting NC design, the piston contacts the seat unless compressed air is supplied to bore B. |

|

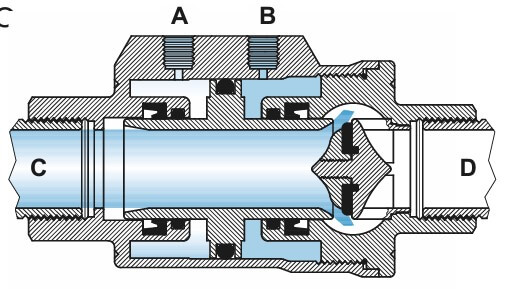

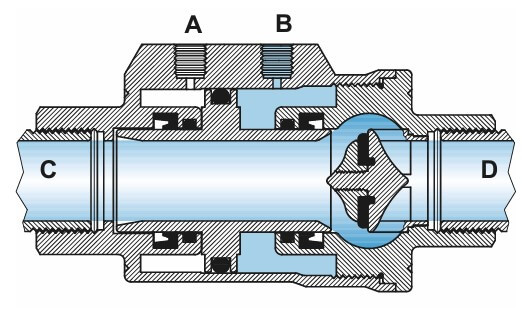

Transition phase

|

| During the transition phase (shown in the picture is the conversion to the open position of the double-acting design), one of the two holes is under pressure. The piston moves axially in alternating open and closed states. In the case of the single-acting NC design, the spring closes and the piston moves towards the seat (if the valve is not controlled). In the case of the single-acting NO design, the spring opens and the piston moves away from the seat (if the valve is not controlled). The valve opening and closing cycle takes less than a second. |

|

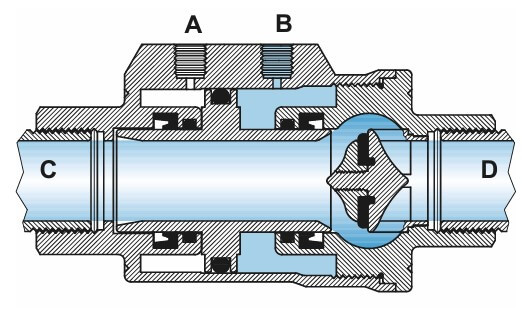

Open valve

|

| When air pressure is applied to bore B (bore A must be relieved) the piston moves away from the seat and the valve is opened. In the case of the single-acting NO design, the piston is furthest from the seat unless the control air pressure is supplied to bore A. |

|

Be the first who will post an article to this item!

Be the first who will post an article to this item!

| Extensive experience is complemented by a wide range of productsOne of the traditional suppliers of pneumatic components is API (Advanced Pneumatic Industries), which was founded in the late 1980s near Milan, Italy. More than three decades of experience have served API to improve the manufacture of all pneumatic components. At the turn of the new millennium, the company invested heavily in its own development and started its own production of valves and cylinders. Since 2007, the API catalogue contains the widest possible range in its field and the products soon travel all over the world. Today, the company offers production and assembly of valves, cylinders and mounting accessories not only in aluminium and steel, but also in stainless steel. In addition to the standard offer, API also offers the possibility of supplying solutions such as valve terminal assemblies or special ATEX designs. |

|

|

Quality certificate at a good price

For all the Italian company's product range, the customer can rely on it. These are products with good technical features, while the price tag is still within reasonable ranges. These words are confirmed by our hundreds of satisfied customers (mainly from industry) for whom API is the preferred brand. Beyond words, however, the reliability of the products is proven by meticulous quality systems such as ISO 9001, CISQ, ICIM or IQNet, whose certificates the products boast. The supply range currently includes pneumatic cylinders, grippers, swing drives, cylinder accessories and mounting brackets, solenoid, pneumatic, mechanical and manual valves, air treatment equipment, fittings, couplings and hoses.

|