Automatic condensate drain LD200

Code: LD200

Product detailed description

Intelligent condensate drain LD200

- state-of-the-art condensate drainage system with automatic operation control, fault detection and no air discharge

- viton FKM membrane for long life, anodized aluminium body with hardened surface for extreme condensate resistance

- double filter strainer to protect the valve system from clogging, level sensing with two capacitive sensors

- adjustable connection allows quick mounting in different directions, electrical connection via DIN 43650B connector

- output with alarms for remote management via 4-pole M12 connector; control panel with two LED signals and test button

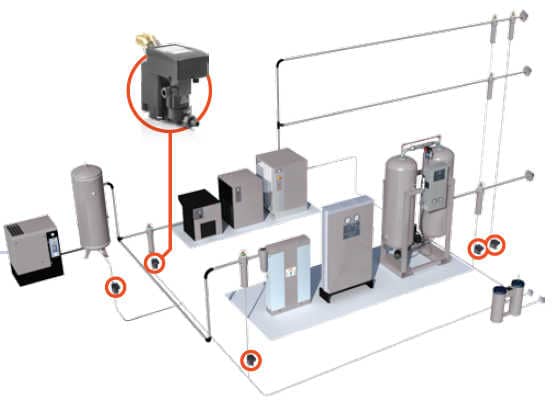

- designed for efficient lossless condensate drainage from dryers, pressure vessels and filters

- important note: the forgiveness capacities are given for the climatic region of Central Europe

Why use Intelligent Condensate Discharge - LD

Condensate can form in the pressure vessel or air receiver when air is compressed. This accumulates in the container and corrosion occurs. Unwanted condensate also binds to the outgoing compressed air and damages other pneumatic components such as pneumatic tools, cylinders and NC machines. In order to prevent this process, it is necessary to drain the condensate from the compressor pressure vessel from time to time to carry out the necessary maintenance of the machine. For easy and comfortable draining, we can choose these automatic condensate drainers, which will perform the necessary maintenance automatically for us. Prevent wear and corrosion in the compressed air system. Small size, no noise and discharge of water alone without compressed air. This does not reduce the air flow as in the case of automatic bleeders.

The main advantages of condensate drains

|

|

Risk reduction

|

|

Usage:

|

The new range of LD condensate drainers uses a system called capacitive drainage for its function. Compared to traditional time forgiveness, this system has several significant advantages.

| Capacitive condensate discharge | Timed release of condensate |

| + only water is discharged, no compressed air | + small dimensions |

| + energy saving | - valve discharges both water and compressed air |

| + no noise and a more pleasant working environment | - increased cost of compressed air production |

| - high noise level |

| Condensate discharge process |

|

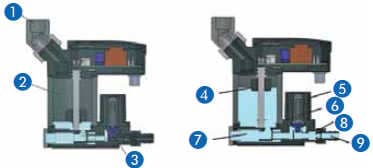

| The condensate enters through connection ❶. In tank ❷ condensate is collected and the diaphragm valve ❸ leaves the drain hole closed. When raising the level the floating body rises ❹ and after reaching the upper level valve ❻ opens, which is controlled by a logic circuit of solenoid valve ❺. Condensate is forgiven and when the level reaches the minimum level, the membrane closes again the drain hole without the compressed air escaping out. In the hose holder has a new filter and flow regulator. |

|

Additional parameters

| Category: | Intelligent electronic LD dischargers |

|---|---|

| Connecting: | 1/2" |

| Dimensions: | 132 x 132 x 164 mm |

| Weight: | 0,7 kg |

| Application: | Piston compressors, Screw compressors, Coolers,, Cyclone separators, Pressure vessels, Dryers, Air filters |

| Electric voltage: | 230 V AC |

| Filter strainer: | Double |

| Maximum inlet pressure: | 16 bar |

| Level sensing: | Two capacitive sensors |

| Equipment:: | Alarm for remote management, Control panel 2xLED signaling, Test button |

| Filter performance: | 150,000 l/min |

| Compressor performance: | 15,000 l/min |

| Dryer performance: | 30,000 l/min |

| Condensate drain: | Automatic |

| Service connection: | Yes |

| Alarm output: | Yes |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Export from Italy to the whole worldAmong the leading manufacturers of compressors and various products for compressed air treatment is the company with Italian roots MARK. A world-renowned company that surpasses even its older competitors with its wide portfolio of products. Today, MARK has one of the largest distribution programs worldwide and thanks to a sophisticated network of sister companies and more than 40 partners, people can meet the products produced in northern Italy literally all over the world. In addition, the company has been a member of the Atlas Copco Group, the largest compressor manufacturer ever, since 1998. |

|

|

Cooperation with the largest manufacturer of compressorsIt is thanks to the cooperation with the Alas Copco Group that the product range has been able to be expanded by hundreds and hundreds of new products, while the existing products have been extensively modernised. As a result, MARK now offers more than 300 models of reciprocating compressors, screw compressors with motors from 2.2 to 160 kW, Ecolife and WIS oil-free compressors and thousands of other air treatment products. All this with ISO 9001:2000 and ISO 14001 quality certificates. You can rely on the MARK brand and with proper use their products will serve you for many years. |

The MARK range can be found below.