Adsorption air dryer ADRY-12

Code: ADRY-12

Related products

Product detailed description

Adsorption compressed air dryer ADRY-12

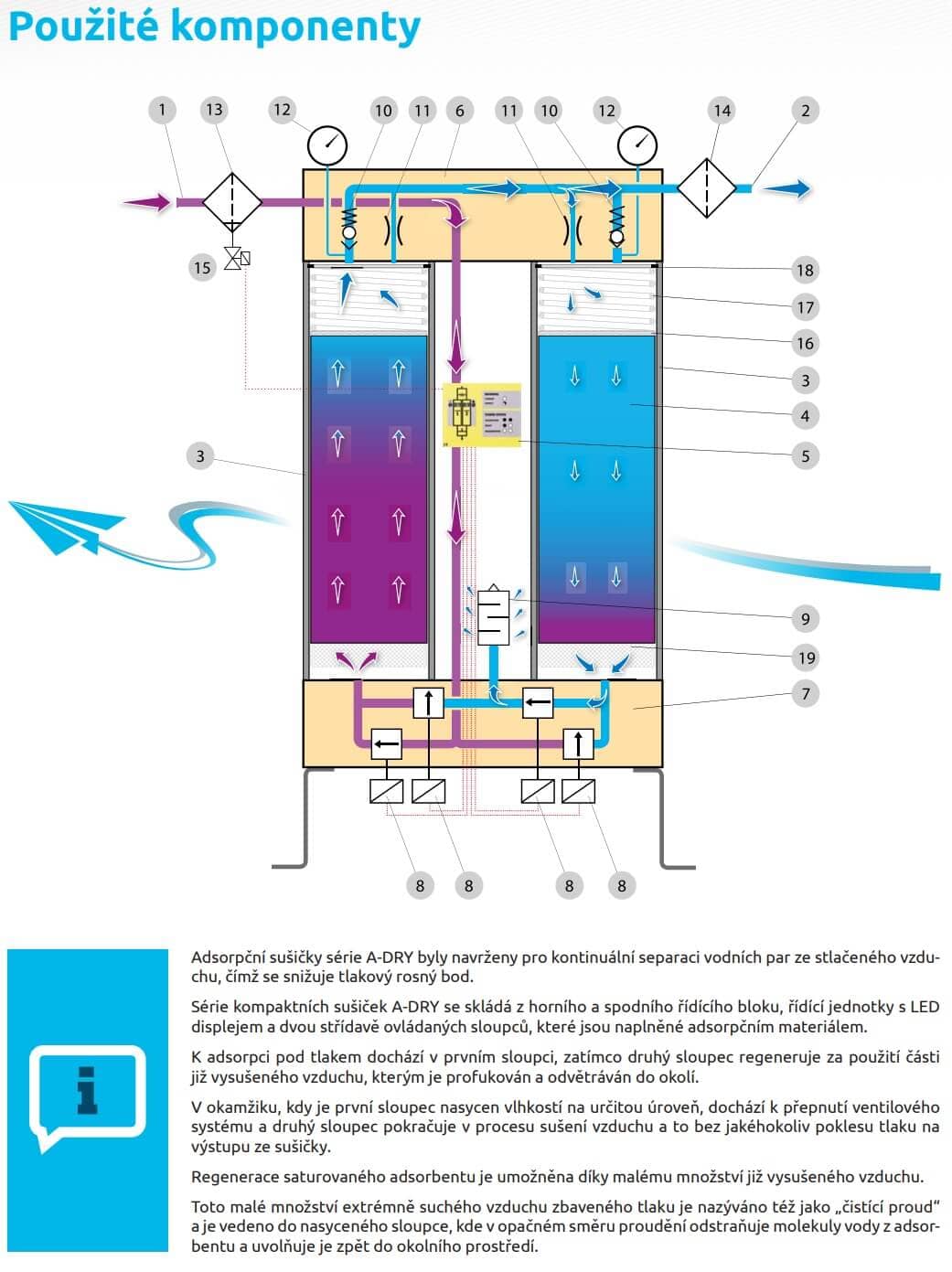

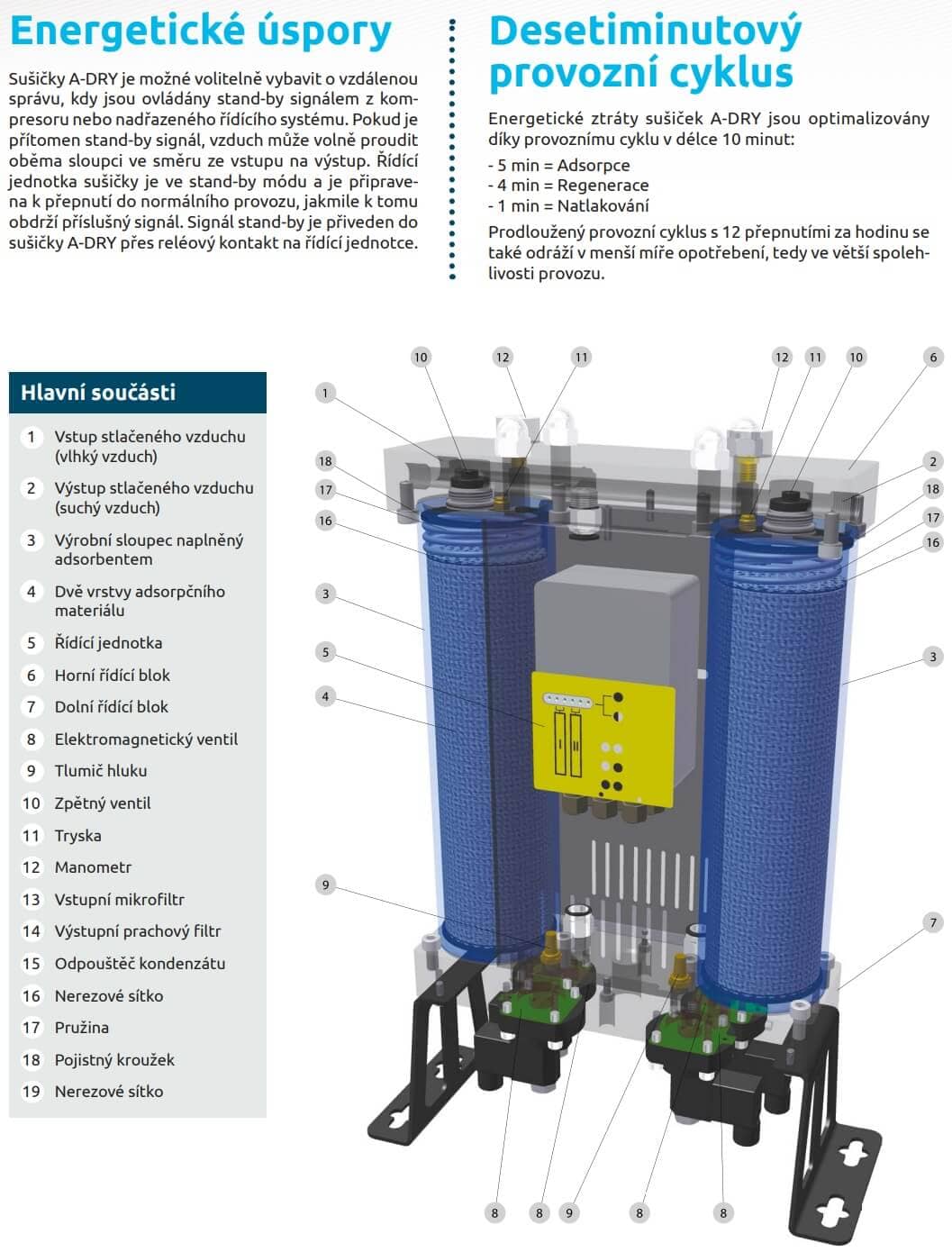

- small adsorption dryers for perfect moisture removal from compressed air with tower regeneration by purging

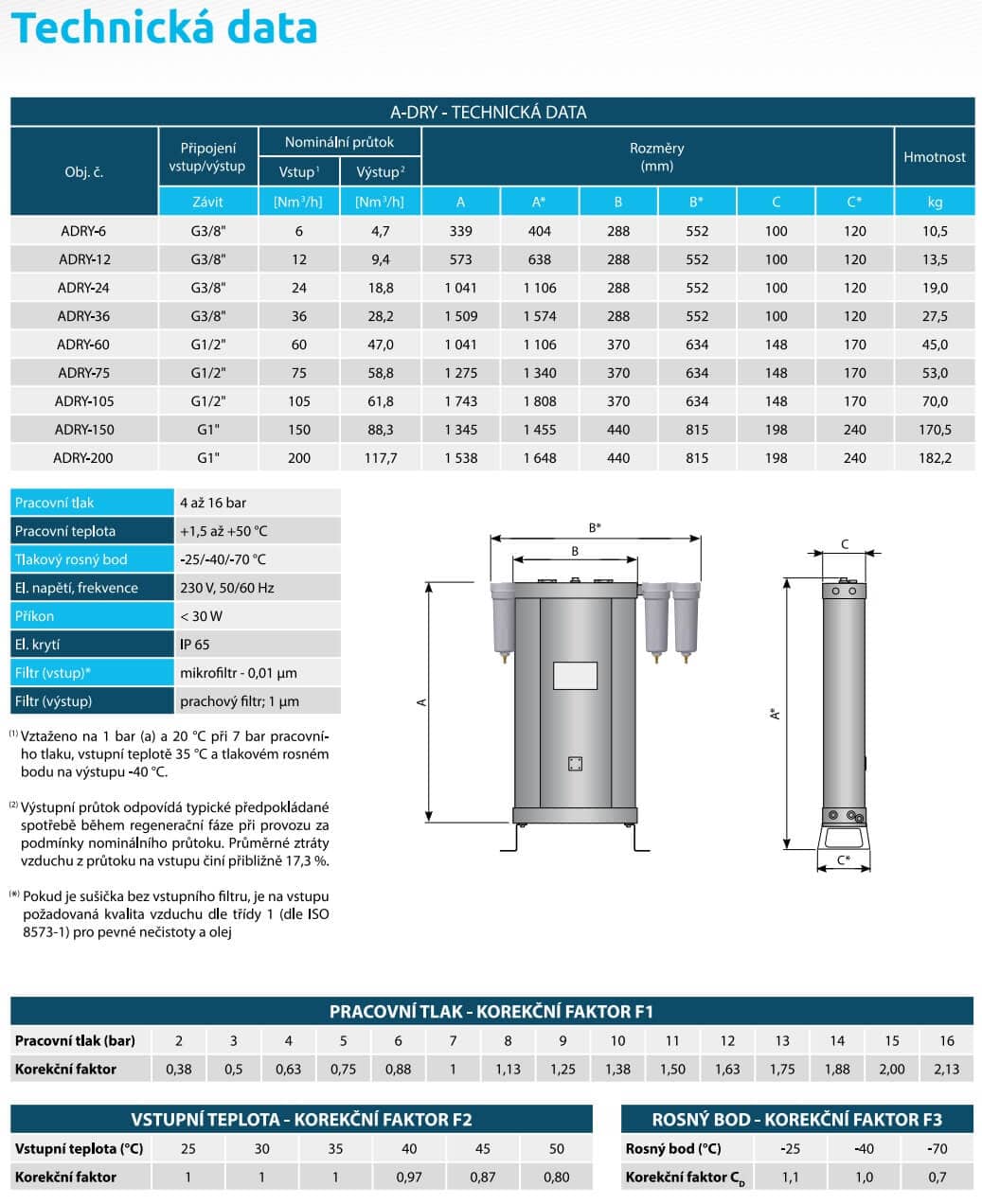

- standard version with dew point -40 °C; on request with dew point -25 °C or -70 °C

- operating temperature +1.5 °C to +50 °C; electrical voltage 230 V 50/60 Hz, electrical protection IP65

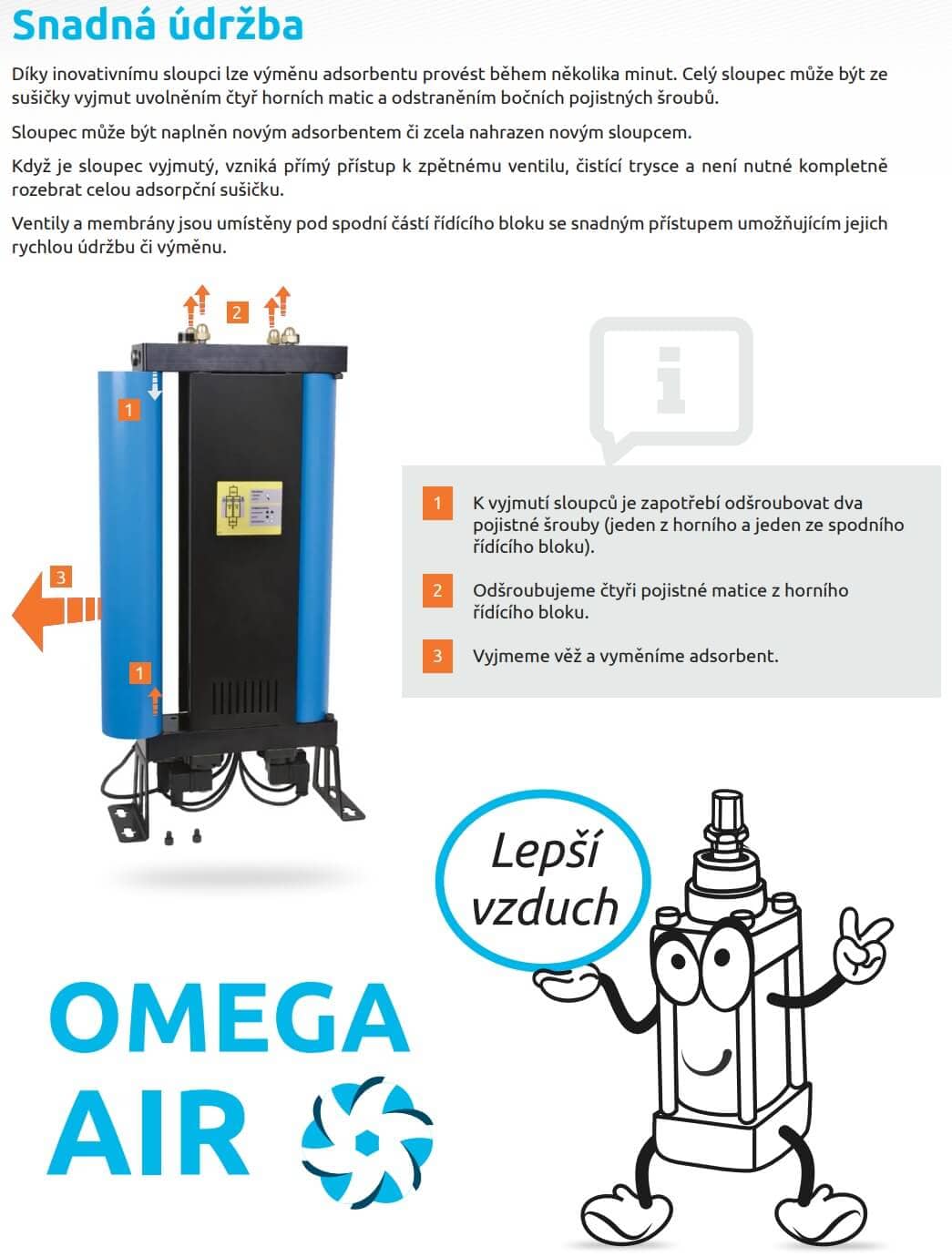

- modular concept allows extremely fast maintenance and reliable operation

- improved adsorption capacity due to the use of two layers of adsorbent - molecular sieve and silica gel

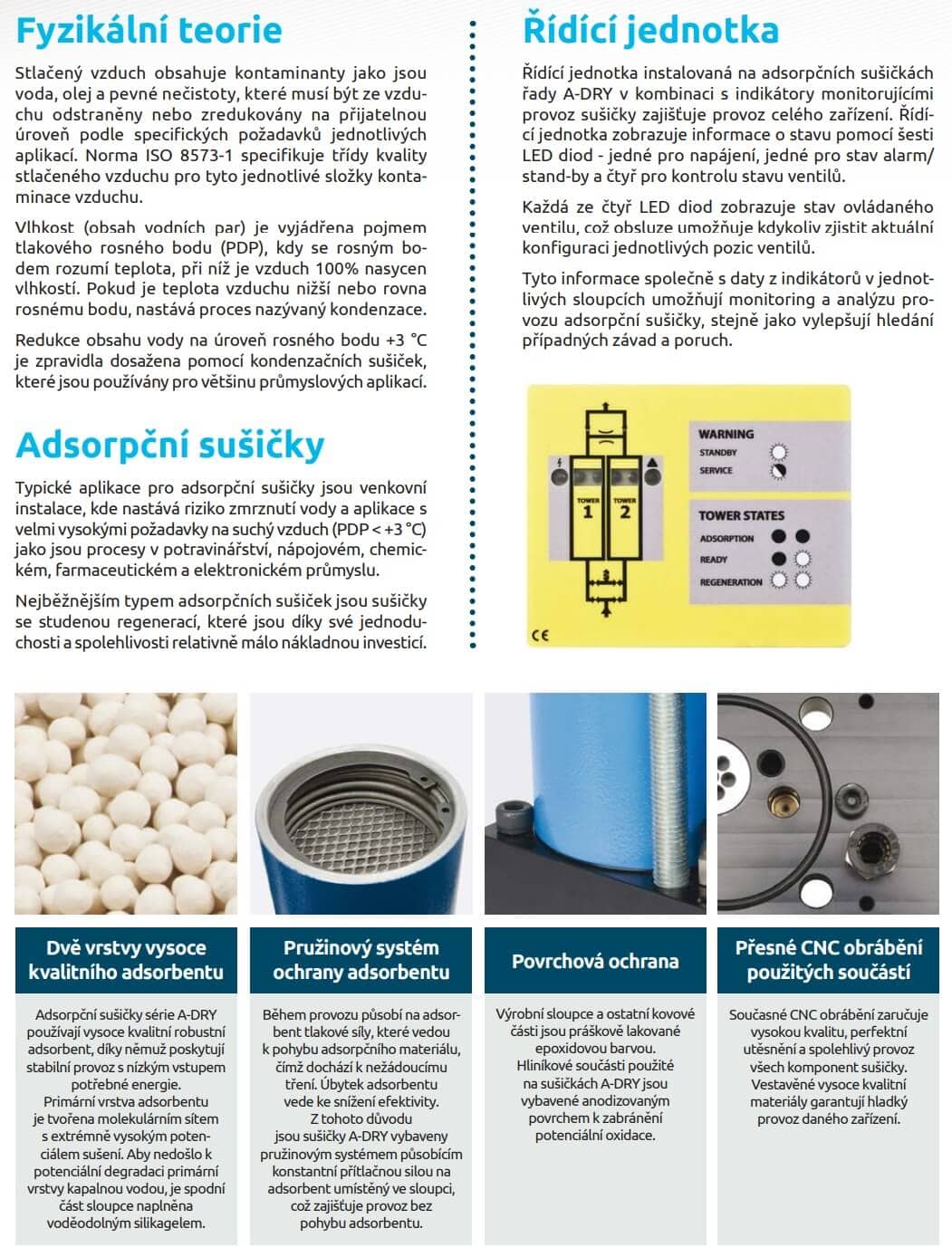

- aDC 4.0 electronic control unit with dew point sensor connection and webserver access

- 4 control valves with diaphragms made of highly durable NBR reinforced PA, pressure gauges on the top side for column pressure reading

- included in the scope of delivery inlet microfilter AFS 0,01 µm and outlet dust filter AFR 1 µm

- designed for all applications with high minimum humidity requirements in compressed air

- important note: A-DRY dryers consume approximately 15-20% of compressed air for regeneration of the production columns

Additional parameters

| Category: | Compressed Air Moisture Removal Air Dryers |

|---|---|

| Pressure: | 16 bar |

| Connecting: | 3/8" |

| Motor power: | 30W |

| Mains voltage: | 230/50 V/Hz |

| Dimensions: | 490 x 20 x 404 mm |

| Flow: | 200 l/min |

| Service interval: | Každé 2 roky |

| Equipment:: | Control unit LED display, Filtration |

| Pressure dew point: | -70°C, -40 °C, -25 °C |

| Dryer type: | Adsorption dryer |

Be the first who will post an article to this item!

Be the first who will post an article to this item!

Alfa and Omega from SloveniaIn the Slovenian capital, Ljubljana, there is a company specialized in compressed air treatment, production of industrial filters and filter inserts, separators or special membrane dryers and other products. Omega Air was founded in 1988 as a family business and soon secured a place in the industry. Over the years, Omega Air's workforce has also grown with increasing production and today the company employs more than 250 people. |

|

|

Omega products are used everywhereA wide range of applications is typical for Omega Air products. Its products are used in heavy industry as well as by private entities. Slovenia's footprint is thus noticeable in industrial sectors such as electrical, gastronomy, pharmaceuticals, moto and also in the chemical-industrial sector. However, the company's main product is special filters, which are exported all over the world. |

No greenhorn in the industryOmega Air also boasts several proprietary innovations and patents that originate in the development department. The company has also been awarded several times for its innovative solutions at the International Engineering Fair itself, which is traditionally held in Hannover, Germany. The Omega Air product range is brought to you by our air compressors company below. |

What Omega Air produces:

|