Adsorption Compressed Air Dryer – Ultra-Dry Air for Demanding Applications

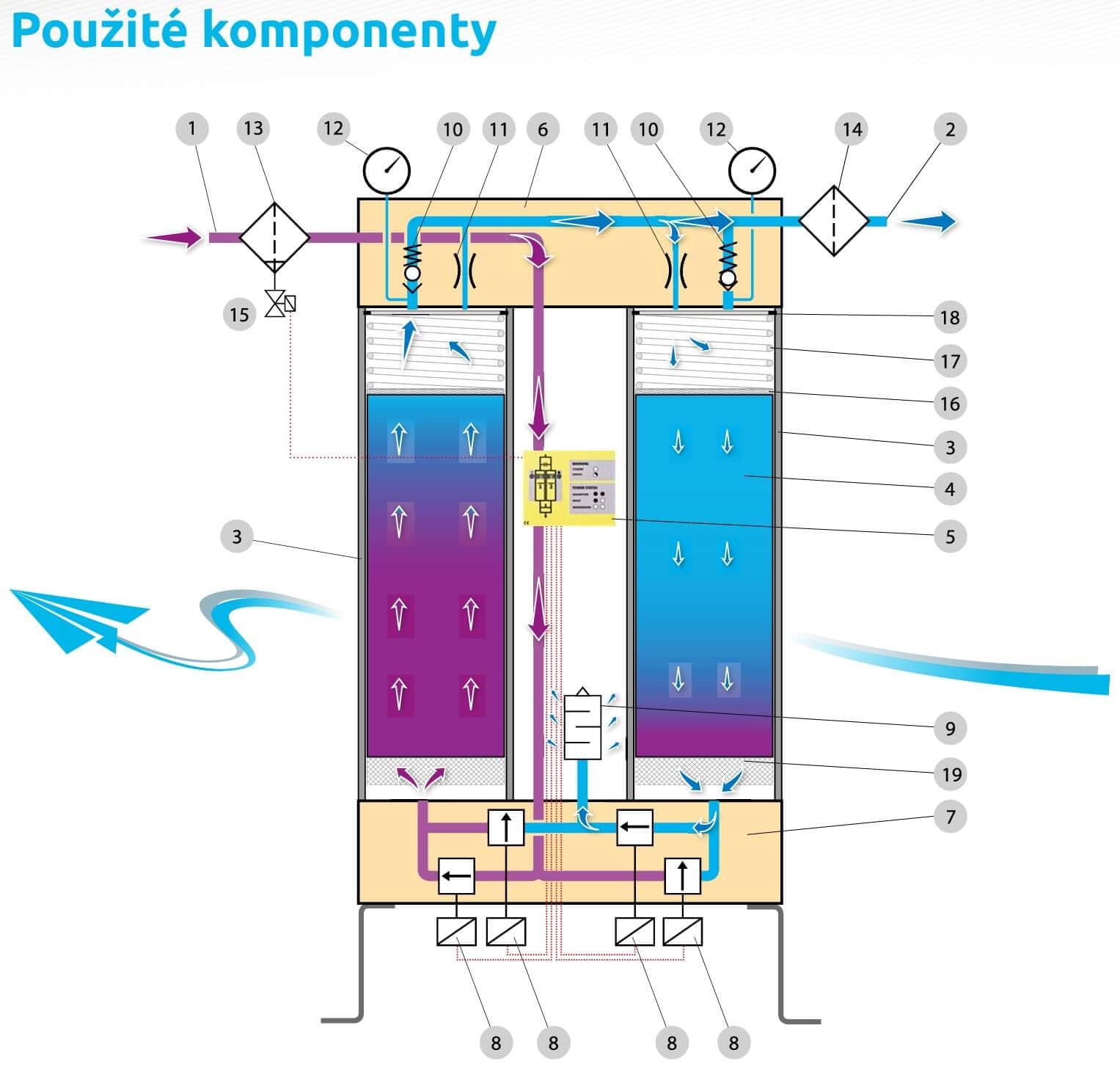

The adsorption dryer dries compressed air using a hygroscopic material that binds moisture. A typical adsorption dryer has two parallel vessels (towers) filled with porous drying media, usually activated alumina or silica gel. In the first tower, humid air flows through the desiccant bed, which adsorbs the water vapor – producing extremely dry air with a pressure dew point typically around –40 °C (depending on the desiccant, down to –70 °C). The second tower undergoes regeneration: the saturated desiccant is purged of previously absorbed moisture. Regeneration can occur either by redirecting part of the dried air through the desiccant at reduced pressure (without heating), or by heating the tower with an electric heater and removing moisture with a small airflow. The towers alternate roles at regular intervals, ensuring a continuous supply of ultra-dry air.

#ShowMore#

Advantages

- Ability to achieve very low pressure dew points (commonly –25 °C to –40 °C, with high-end models reaching –70 °C), suitable for sub-zero environments or moisture-sensitive processes.

- High moisture removal efficiency – air leaving the adsorber contains virtually no water vapor (extremely low relative humidity).

- Wide range of models and capacities: from small units to large industrial dryers for central compressed air systems.

- Modern units with external heating or smart regeneration control reduce energy use and minimize compressed air loss.

Disadvantages

- Higher initial cost and more complex construction compared to refrigerated dryers (includes more components, valves, and control systems for tower switching).

- Potentially high energy consumption: standard heatless models consume approx. 15–20% of the dried air for desiccant regeneration, reducing available supply for end use.

- Requires regular maintenance and media replacement: desiccant becomes saturated or contaminated over time and must be replaced periodically (typically after several thousand hours, depending on usage and air quality).

- Requires high-quality pre-filtration: oil aerosols and dirt must be removed before the dryer to protect the desiccant. Contaminants can severely degrade performance or destroy the media.

Applications

Adsorption dryers are used where top-quality, ultra-dry air is required. This includes pharmaceutical and food industries (packaging, bottling, beverage production), healthcare, electronics and precision engineering, chemical and petrochemical industries, and high-end paint applications with strict air purity requirements. They are essential where air lines are exposed to outdoor or freezing conditions – air with a dew point of –40 °C reliably prevents condensation and icing in pipes. Common in offshore oil platforms, railway brake systems, and automated freezer storage systems.

Comparison with Other Dryer Types

Compared to refrigerated dryers, adsorption dryers deliver significantly drier air, but at the cost of higher investment and operating expenses. For general workshop use, refrigerated dryers are often preferred if a dew point of +3 °C is sufficient. Adsorption technology is essential where other methods fall short – for example, membrane dryers are not economical for large air volumes or cannot reach such low dew points. On the other hand, for very small air flow needs, a membrane dryer may be a viable alternative to a compact adsorption unit. Adsorption dryers are often paired with an additional filtration stage – such as activated carbon columns that remove oil vapors and odors, ensuring perfectly clean and dry air even for the most demanding applications.

Reminder: To ensure proper function and long service life of the adsorption dryer, it is essential to install effective compressed air filters (mechanical pre-filter and coalescing filter). These filters capture oil, water aerosols, and dust before air enters the desiccant tower. This prevents desiccant damage and loss of dryer performance. If unsure which drying level you need, visit our knowledge base – we’ll gladly help you choose the right dryer and filtration setup.

-

RDP condensation dryers; pressure dew point +3 °C

RDP condensation dryers; pressure dew point +3 °C

-

.jpg) Condensation dryers WDF; dew point +3°C with filters

Condensation dryers WDF; dew point +3°C with filters

-

-hankison-susicka-vzduch-kompresor-tllak-kondenzace-rosny-bod.jpg) HDI air dryers; pressure dew point +4°C

HDI air dryers; pressure dew point +4°C

-

RDL condensing dryers; pressure dew point +5°C

RDL condensing dryers; pressure dew point +5°C

-

Cool air dryers; pressure dew point +5°C

Cool air dryers; pressure dew point +5°C

-

MDX air dryers; pressure dew point +3°C

MDX air dryers; pressure dew point +3°C

-

.jpg) ADRY air dryers; smaller adsorption -40°C

ADRY air dryers; smaller adsorption -40°C

-

BDRY air dryers; large adsorption -40°C

BDRY air dryers; large adsorption -40°C

-

MADRY air dryers; membrane -40°C

MADRY air dryers; membrane -40°C

-

Activated carbon columns; activated carbon separation

Activated carbon columns; activated carbon separation

The ADRY-105 Series Adsorption Dryer was designed for continuous separation of water vapor from compressed air at flow rates up to 1,750 l/min. Reduces the pressure dew point...

Dew point sensor including cable - for air saving regeneration - ADRY-OS. A-DRY dryers can operate in two operating modes depending on the settings of the control unit. Fixed...

The ADRY-6 series adsorption dryer has been designed for continuous separation of water vapour from compressed air at flow rates up to 100 l/min. Reduces the pressure dew point...

After one year of operation, the ADRY-105 series Omega Air adsorption dryer service KIT includes a replacement microfilter cartridge, dust filter and replacement silencers for...

Service KIT 2 years of operation of the adsorption dryer Omega Air series ADRY-24 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer,...

Service KIT 2 years of operation adsorption dryer Omega Air series ADRY-36 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer, check...

Service KIT 2 years of operation of the adsorption dryer Omega Air series ADRY-60 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer,...

Service KIT 2 years of operation of the adsorption dryer Omega Air series ADRY-200 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer,...

The ADRY-60 series adsorption dryer was designed for continuous separation of water vapour from compressed air at flow rates up to 1,000 l/min. Reduces the pressure dew point...

Measuring chamber for dew point sensor - for regeneration air saving - ADRY-MK. A-DRY dryers can operate in two operating modes depending on the settings of the control unit....

Service KIT 2 years of operation adsorption dryer Omega Air series ADRY-12 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer, check...

Service KIT 2 years of operation adsorption dryer Omega Air series ADRY-6 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer, check...

Service KIT 2 years of operation of the adsorption dryer Omega Air series ADRY-75 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer,...

After one year of operation, the service KIT for the Omega Air adsorption dryer series ADRY-150 to ADRY-200 includes a replacement microfilter cartridge, dust filter and...

The ADRY-24 series adsorption dryer was designed for continuous separation of water vapour from compressed air at flow rates up to 400 l/min. Reduces the pressure dew point down...

Service KIT 2 years of operation of the adsorption dryer Omega Air series ADRY-105 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer,...

Service KIT 2 years of operation of the adsorption dryer Omega Air series ADRY-150 includes a replacement filter cartridge ;microfilter, dust filter and replacement silencer,...

After one year of operation, the service KIT for the Omega Air ADRY-60 to ADRY-75 series adsorption dryer includes a replacement microfilter cartridge, dust filter and...

The ADRY-150 Series Adsorption Dryer was designed for continuous separation of water vapor from compressed air at flow rates up to 2,500 l/min. Reduces the pressure dew point...

After one year of operation, the service KIT for the Omega Air adsorption dryer series ADRY-6 to ADRY-36 includes a replacement microfilter cartridge, dust filter and...

Cable for analogue output of adsorption dryers - BDRY-AO. B-DRY dryers can operate in two operating modes depending on the settings of the control unit. Fixed Cycle Mode -...

Measuring chamber for dew point sensor - for regeneration air saving - BDRY-MK. B-DRY dryers can operate in two operating modes depending on the settings of the control unit....

The ADRY-12 series adsorption dryer has been designed for continuous separation of water vapour from compressed air at flow rates up to 200 l/min. Reduces the pressure dew point...

The ADRY-200 Series Adsorption Dryer was designed for continuous separation of water vapor from compressed air at flow rates up to 3,333 l/min. Reduces the pressure dew point...

The ADRY-36 series adsorption dryer has been designed for continuous separation of water vapour from compressed air at flow rates up to 600 l/min. Reduces the pressure dew point...

The ADRY-75 Series Adsorption Dryer was designed for continuous separation of water vapor from compressed air at flow rates up to 1,250 l/min. Reduces the pressure dew point...

The BDRY-1000 Adsorption Dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 13,067 l/min at a maximum pressure of 16 bar...

Adsorption dryer BDRY-110 designed for permanent separation of water vapour from compressed air with a flow rate of up to 1 433 l/min at a maximum pressure of 16 bar and...

Adsorption dryer BDRY-1200 designed for continuous separation of water vapour from compressed air with a flow rate of up to 15,050 l/min at a maximum pressure of 16 bar and...

Adsorption dryer BDRY-150 designed for permanent separation of water vapour from compressed air with a flow rate of up to 1 958 l/min at a maximum pressure of 16 bar and...

The BDRY-200 adsorption dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 2,617 l/min at a maximum pressure of 16 bar and...

The BDRY-250 Adsorption Dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 3,400 l/min at a maximum pressure of 16 bar and...

Adsorption dryer BDRY-300 designed for permanent separation of water vapour from compressed air with a flow rate of up to 4,183 l/min at a maximum pressure of 16 bar and...

Adsorption dryer BDRY-400 designed for permanent separation of water vapour from compressed air with a flow rate of up to 5 358 l/min at a maximum pressure of 16 bar and...

Adsorption dryer BDRY-600 designed for continuous separation of water vapour from compressed air with a flow rate of up to 7,708 l/min at a maximum pressure of 16 bar and...

Adsorption dryer BDRY-800 designed for permanent separation of water vapour from compressed air with a flow rate of up to 10 058 l/min at a maximum pressure of 16 bar and...

The FDRY-1200 Adsorption Dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 15,600 l/min at a maximum pressure of 16 bar...

The FDRY-1500 Adsorption Dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 19,500 l/min at a maximum pressure of 16 bar...

The FDRY-2000 Adsorption Dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 26,000 l/min at a maximum pressure of 16 bar...

The FDRY-2500 Adsorption Dryer is designed for continuous separation of water vapour from compressed air with a flow rate of up to 32,500 l/min at a maximum pressure of 16 bar...